PRODUCTS

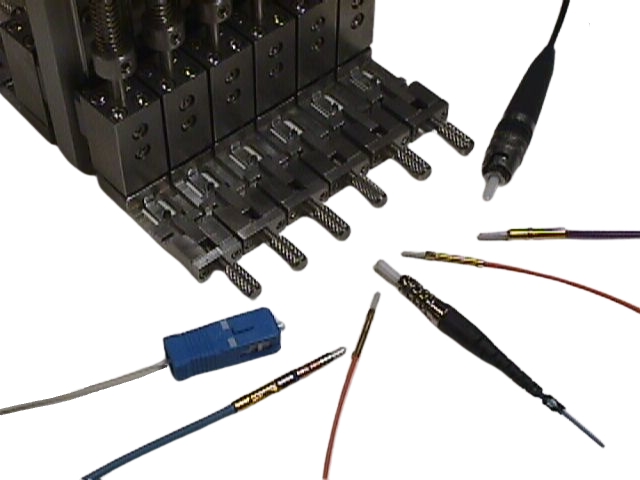

Universal Connector Fixtures

KrellTech’s unique Universal Workholder supports all UPC connectors, ferrules, and Mil-spec termini in a single polishing jig. Components supported include SC, FC, ST, LC, MU, E2000, SMA 905, SMA906, M29504, LuxCis, ARINC 801, ELIO, MC5, RSC and many others.

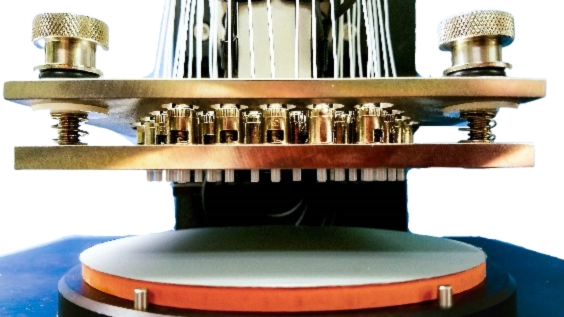

High Capacity UPC Connector Workholders

Maximize production through-put with KrellTech's HiCap Workholders. Up to 28 UPC connectors can be quickly loaded and processed at a rate of 6 connector per second. An integrated pressure control mechanism guarantees positive contact across all connector endfaces.

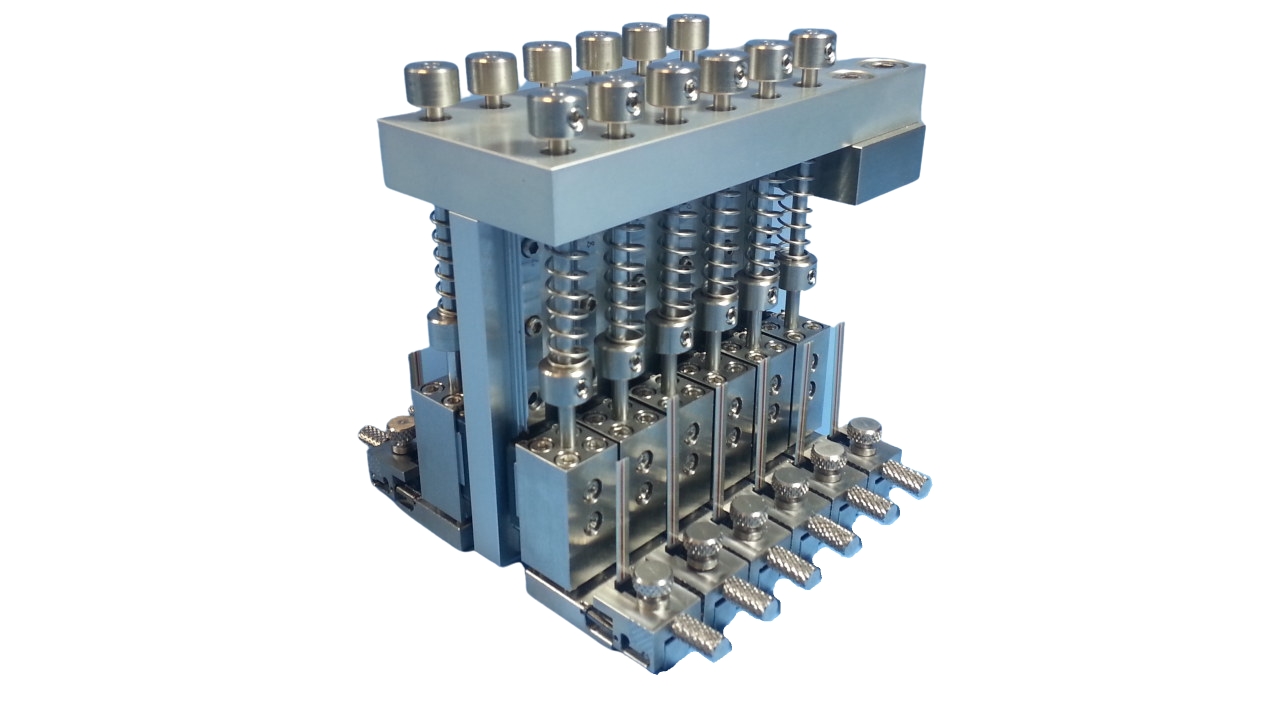

Multi-Fiber Connector Fixtures

These fixtures are designed to meet the stringent endface geometries such as flatness and fiber protrusion required for multi-fiber ferrules. Connectors supported include MT, MTP, MTO, MTx and MT-RJ. Both UPC and angled fixture are available. Fixtures also available to support MMC connectors with TMT ferrules. All fixtures feature fast and positive "tool-less" ferrule loading. Simply (1) retract the clamp, (2) insert ferrule and (3) lock the clamp. Like all Krell workholders these fixtures feature independent suspension for equalized pressure distribution and optical aligned ferrule holders for superior endface geometry control.

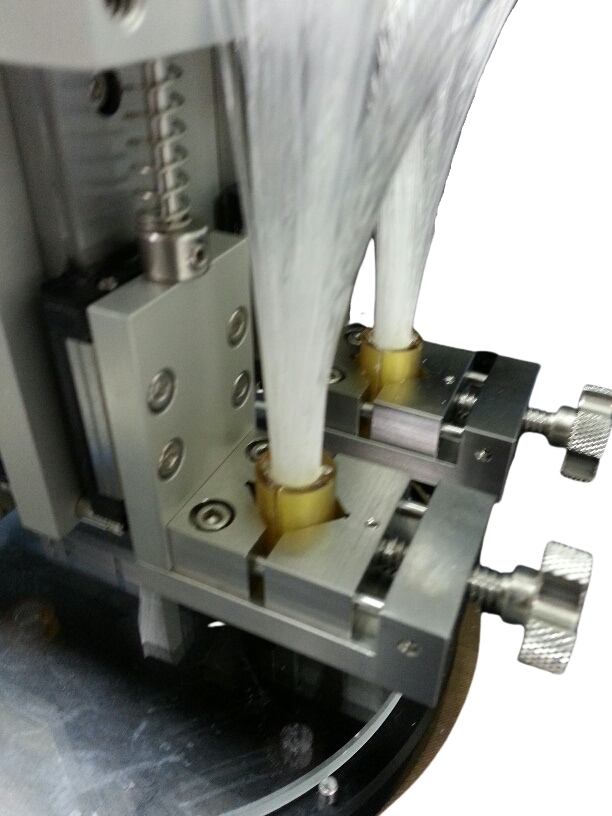

Plastic Optical Fiber Workholder

Plastic optical fiber (POF) workkholders can polish over 500 fibers in less than 5 minutes. Adaptable bushing design can accommodate a large variety of fiber diameters. This fixture also features Krell's patented independent suspension design for superior pressure control.

Industry Standard and Custom Polishing Fixtures

Workholders are available for all industry standard optical connectors. These include SC, FC, ST, LC and many others. Both UPC and APC endface geometries are supported. Adapters can also be used for bare fiber polishing in these fixtures. KrellTech’s engineering team develops customized polishing equipment for all applications and optical requirements. We have designed fixtures for products ranging from cannula and illumination bundles, to waveguides and fiber arrays. When requesting a quotation please provide detailed application specifications and attach all relevant drawings and information.

Image captions, left to right:

- Polishing workholder for medical cannula.

- Polish all 2.5mm connectors and ferrules with this fixture.

- Polishing fixture supports all ferrules 1mm to 3.2mm UPC geometry.

- AVAGO HFBR-4531 and 4532Z.

- Biconic connector jig with length control.

- High power connector polishing fixture.

- Adjustable, large diameter bare fiber LD workholder.

- Standard FC/APC 8 degee workholder fixture.

- FlexGrip workholder for large and odd-shaped components.

- Glenair GHD APC fiber optic termini.

- Bulkhead fiber optic connectors.

- M29504 termini with short breakout.

- Glass ferrule with angle polished endface.

- Universal APC workholder with angled v-groove.

- Universal angled polishing fixture.

- Glass slide polishing.

- Glass die

- Micro glass blocks

Polishing Films

Krell offers a variety of polishing films and lapping films for optical connector and bare fiber processing. Diamond, silicon carbide, aluminum oxide and silicon dioxide abrasives and slurries are available in a variety of grit and particle sizes. Specialize flock films can be used for controlling fiber protrusions with multifiber MTP, MTX and MT-RJ connectors. Standard film diameters are 5”, 4”, and 2”. Special film orders can be accommodated.

Precision Rubber Pads, Glass Disks & Wear Liners

Rubber polishing pads and glass polishing discs are crucial for controlling connector endface geometries such as apex offset, radius of curvature, and fiber protrusion/undercut. Krell offers precision ground rubber pads necessary to achieve these Telcordia specification. Rubber pads are available in various durometers (hardness) and diameters. Glass disks are also available for processing flat surfaces that are required for bare fibers, SMA connectors, and MT style multifiber connectors.

Wear liners are used with all KrellTech polishers to ensure smooth and controlled polishing, eliminating the need for messy lubricants. Liners are easily replaced on both the base polisher and platen contact surfaces.

CleanTouch™

CleanTouch™ is an economic and ergonomic device for cleaning optical connectors and bare fibers. By merely touching a connector ferrule against the CleanTouch substrate, all contaminants are removed. Delicate bare fibers are easily cleaned without the possibility of breakage or damage to the endface surface.

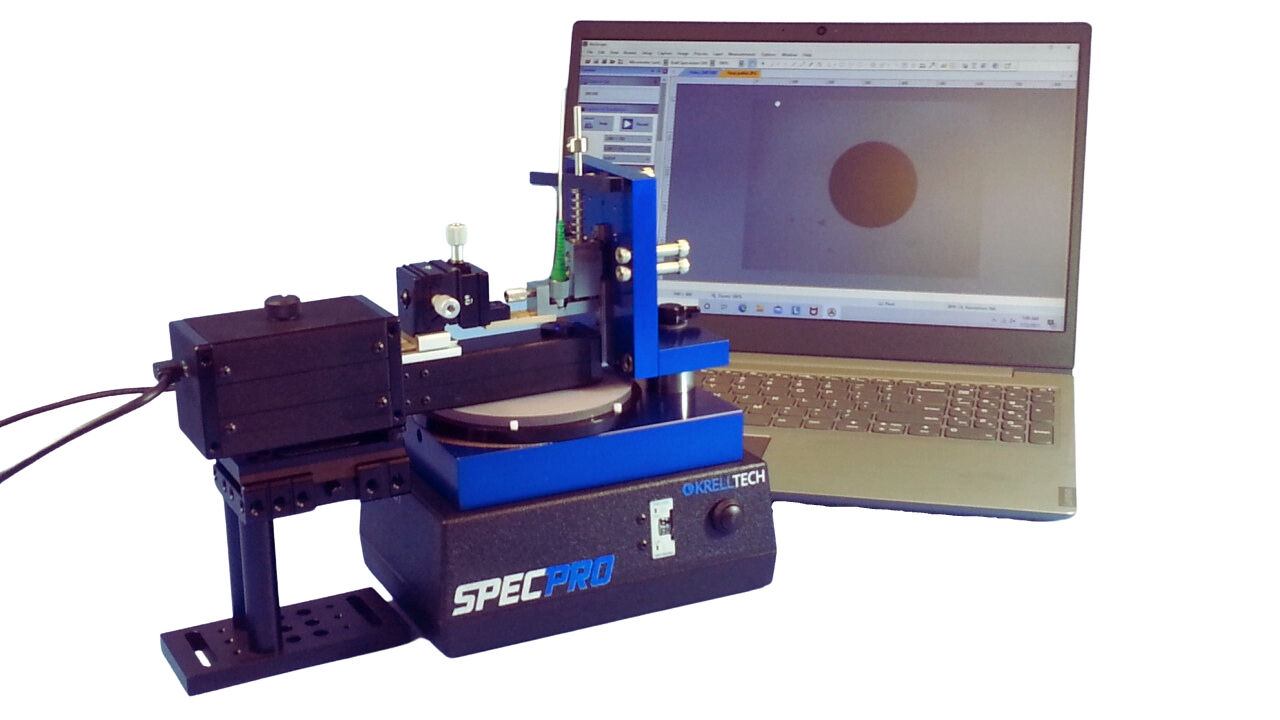

SpecVision™ Video Inspection Scope

SpecVision™ is a video probe and fiberscope that engages directly with Krell polishing machines. This permits the viewing of polished optical surfaces while connectors or bare fibers are still loaded in the polisher. This in-line video inspection technique minimizes material handling and potential damage/contamination that may occur when transferring components from the polisher to a traditional microscope. SpecVision™ can interface with Scepter™, NOVA™, SpecPro™ and Rev™ Polishers.

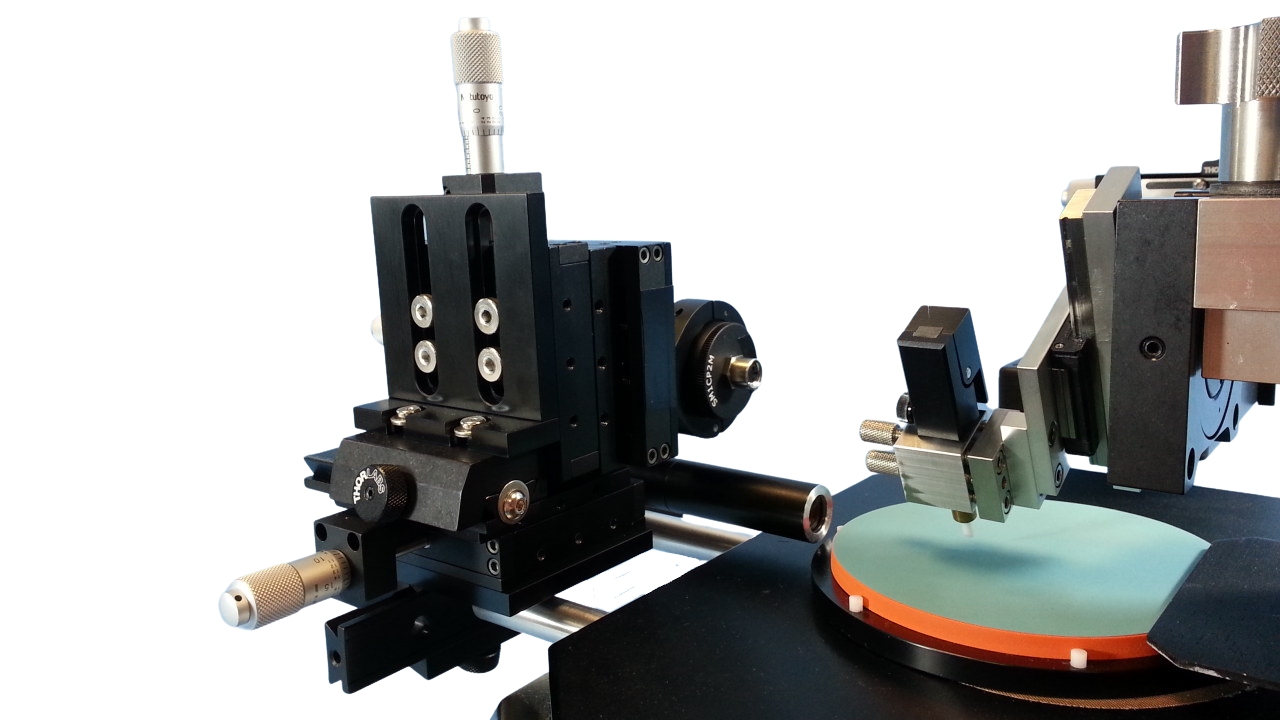

NOVA™ Profile Inspection Module

NOVA™'s Profile Videoscope allows the real-time monitoring of component polishing. This videoscope aids with bare fiber/component positioning and confirms process completion. Teamed with measurement software, this system verifies the endface geometry of fibers, waveguides and arrays.