KRELLTECH INTRODUCES THE GEO SYSTEM

Release, Nov. 6, 2023, 9 a.m.

Revolutionary Polishing Platform Addresses the Processing Challenges of PICs and Waveguides

Neptune City, NJ: November 6, 2023 – KrellTech, the leading manufacturer of optical polishing and inspection equipment, announced today its new GEO™ Processing System.

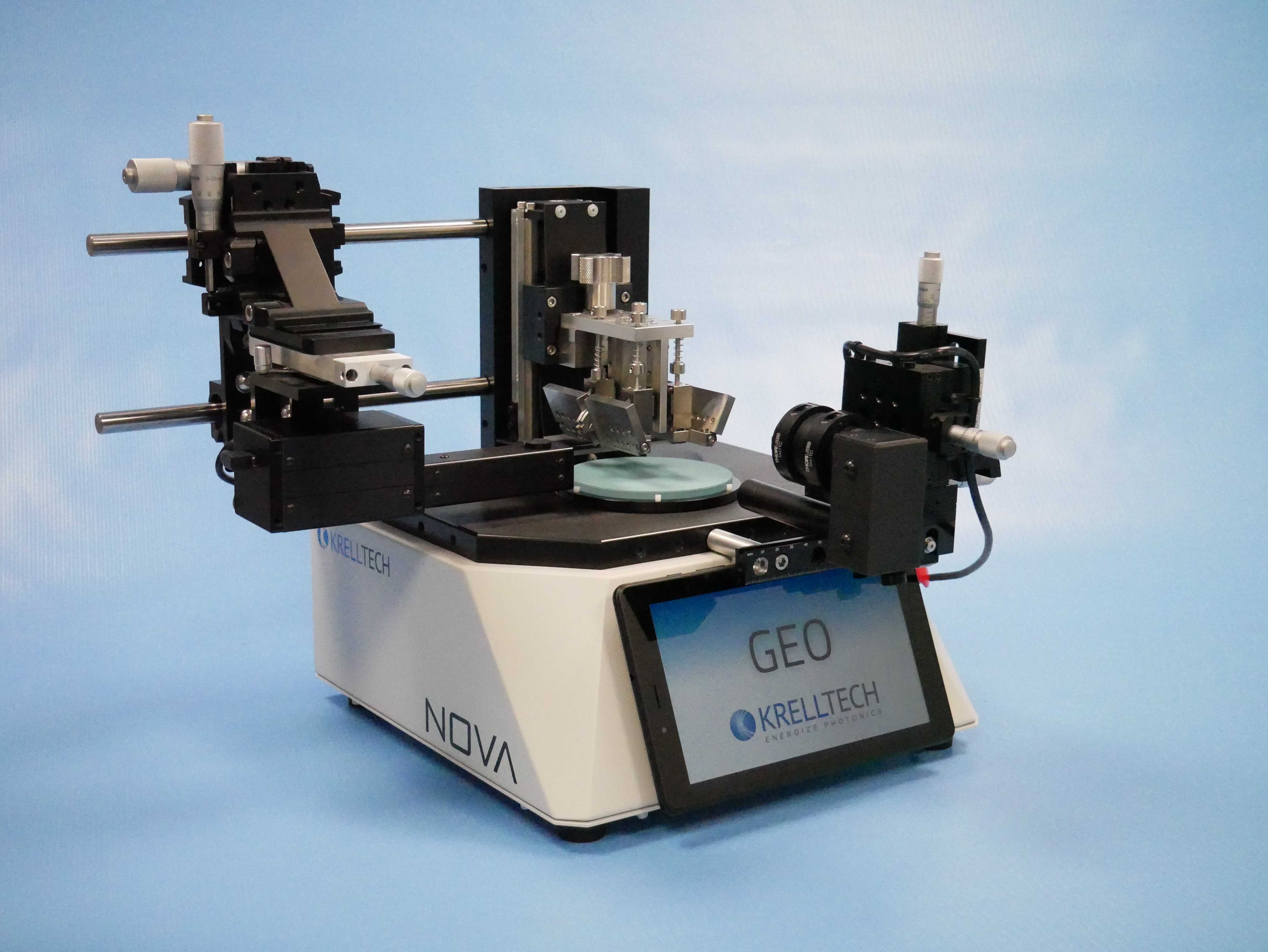

GEO™, based upon the proven NOVA™ polisher, is specially configured to address the unique requirements and processing challenges of the emerging photonic integrated chip (PIC) industry. Its workholder fixtures provide adjustable mounting mechanisms to accommodate varying chip dimensions, while taking into consideration the fragile and sensitive waveguide surface features. Flat, angled and multi-faceted geometries can be formed on optical chip edges and endfaces.

Chris Bruno, Vice President of Engineering, has directed the design efforts of the engineering team behind GEO™. “Krell has always tackled the more challenging photonic applications, ranging from bare fiber polishing and shaping, to esoteric medical devices and optical probes. The new technologies we developed for these applications have been incorporated and optimized in GEO™ to solve the specialized demands posed by PICs and waveguides.”

GEO™ can manipulate chip positioning and movement to a micron level. “This enables precise material removal while maintaining critical lengths”, says Bruno. “Combined with GEO™’s unique “microfeed” advancement feature, superior dimensional tolerance control can be achieved and maintained on a consistent basis.” GEO offers wireless tablet control using a familiar Android interface for ergonomic operation. A “manual” mode is ideal for initial process development, whereas “programmed” modes allow for seamless deployment into production environments.

While accurate and repeatable polishing is a must for PIC optical performance, its quality must be verified and assured. Geo™ integrates vision systems to accomplish the task of quality assurance while PIC chips and optical waveguides are still loaded in the workholder fixture. A profile videoscope allows viewing of the polishing process in real time with the ability to measure final geometries and monitor material removal. Polished surfaces can also be scrutinized with GEO™’s in-line inspection videoscope. Hence, GEO™ is its own workcell, transforming its operating technician into both a processer and QA inspector.

“KrellTech has had a history of product innovation and has become the “go-to” company for emerging optical industries”, added Bruno. “The introduction of GEO™ solidifies Krell as the leader in photonic innovation.”