POLISHING FILM, PADS, LINERS

Polishing Films for Precision Optical & Photonic Processing

🔹 Silicon Carbide Films – Versatile for fiber optic, waveguide, and PIC finishing

🔹 Aluminum Oxide Films – Ideal for controlled surface polishing and material refinement

🔹 Final Polish Films – For ultra-fine surface finishing

🔹 Flock Films – Designed for fiber protrusion control in multifiber connectors

✔ Customized Solutions – We accommodate unique polishing needs.

✔ Quality Control – Precision-engineered films for optical and photonic applications.

✔ Timely Sourcing – Reliable stock availability and fast order fulfillment.

✔ Expert Advice – Backed by 30+ years of industry experience.

Precision Rubber Pads, Glass Disks & Wear Liners

KrellTech offers precision-engineered rubber polishing pads, glass polishing disks, and wear liners designed for maintaining connector endface geometries, including apex offset, radius of curvature, and fiber protrusion/undercut. Our Telcordia-compliant rubber pads come in multiple durometers (hardness levels) to achieve the ideal finish for fiber optic connectors.

For flat surface processing, we provide glass disks, ideal for bare fibers, SMA connectors, and MT-style multifiber connectors.

Wear liners ensure smooth, controlled polishing across all KrellTech polishers, eliminating the need for messy lubricants. They are easily replaceable for both the base polisher and platen contact surfaces, improving system longevity and consistency.

Available Polishing Pads & Glass Disks

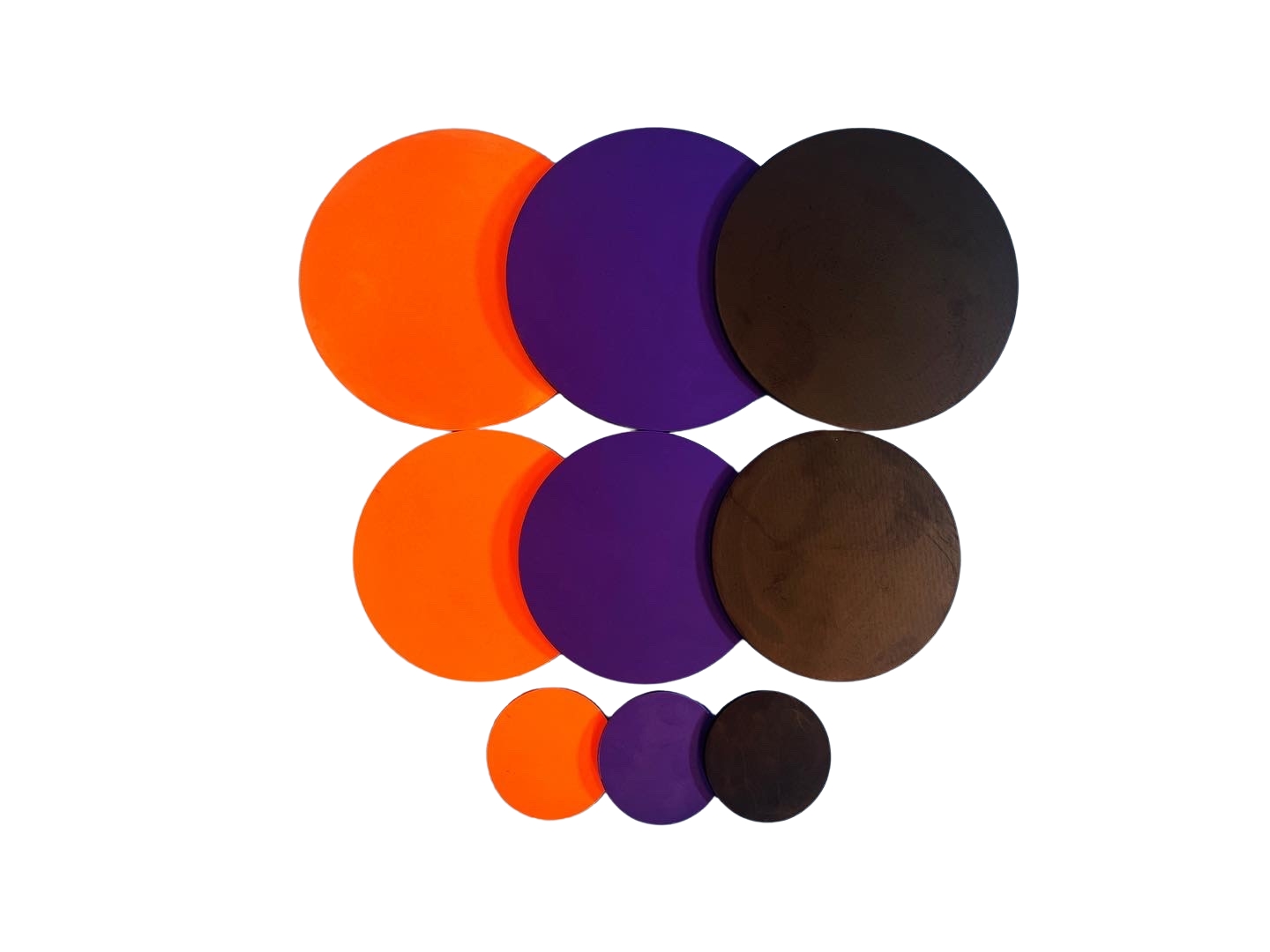

Our polishing pads and disks are available in 2”, 4”, and 5” diameters, with multiple durometer options:

🔹 40D Orange Pad – Flexible for controlled geometry adjustments

🔹 70D Purple Pad – Medium-hard for precision polishing

🔹 90D Black Pad – Firm support for maintaining surface integrity

🔹 Glass Disk – Ideal for flat surface processing

🔹 Hybrid Pads (Glass/Rubber) – Available in Black (60D) and Orange (70D)

🔹 Custom Requests – Enter specifications in the Custom Application Notes field

Wear Liners for KrellTech Polishers

Wear liners extend the life of KrellTech polishers and improve polishing consistency.

✔ Platen Wear Liners – Ensures consistent polishing contact and minimizes wear

✔ Base Wear Liners – Protects the main polishing system for extended use

Why Choose KrellTech Polishing Accessories?

✔ Telcordia-Compliant – Designed to meet industry standards for optical polishing

✔ Customizable Options – Hybrid pads, multiple durometers, and custom requests

✔ Precision-Engineered – Optimized for controlled fiber geometry and repeatability

✔ Enhanced Equipment Longevity – Wear liners improve system durability and performance