POLISHING FIXTURES

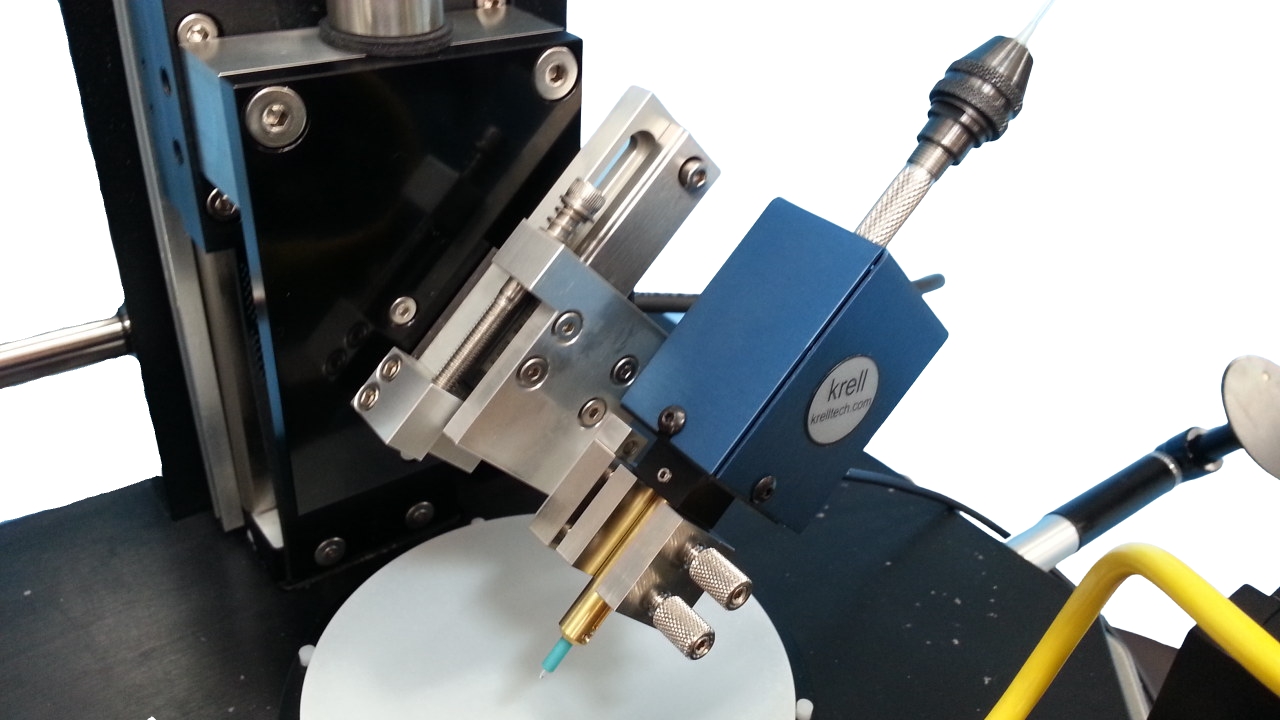

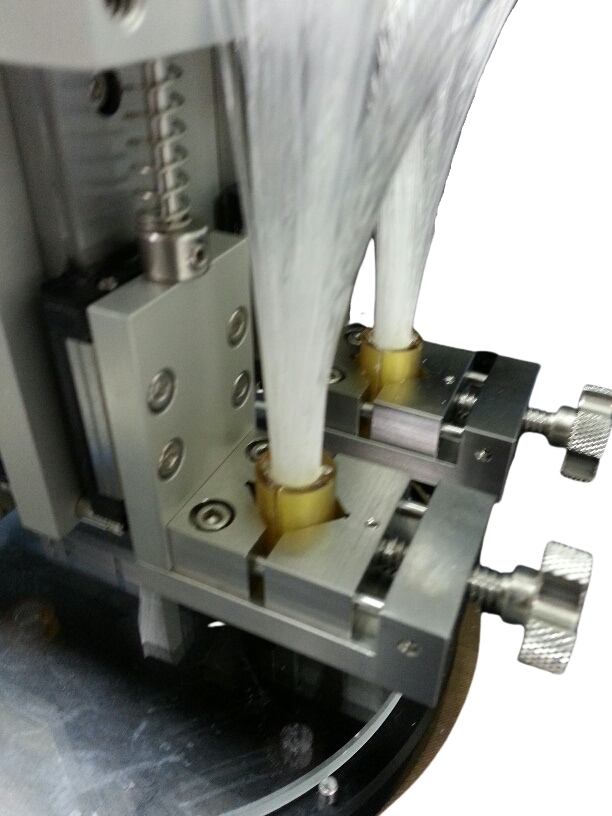

Orbit™ Bare Fiber Coning and Chisel System

Orbit™ enhances NOVA™'s bare fiber processing with conical and chisel tip shaping. Unique fiber tip geometries can be formed for lensing, sensing and light guiding applications.

The fiber rotation module can be mounted on standard NOVA™ variable angle and waveguide workholders. Fiber "spin" speed is user adjustable, and can be set for continual rotation or the unique "360 auto-reverse" motion that prevent fiber twisting and torquing.

All variables are entered and selected via a touchscreen on the Orbit™ controller. When combined with NOVA™ Auto-Angle Workholders, Orbit™ precisely positions the polishing fixture at the designed angle on a repeatable basis.

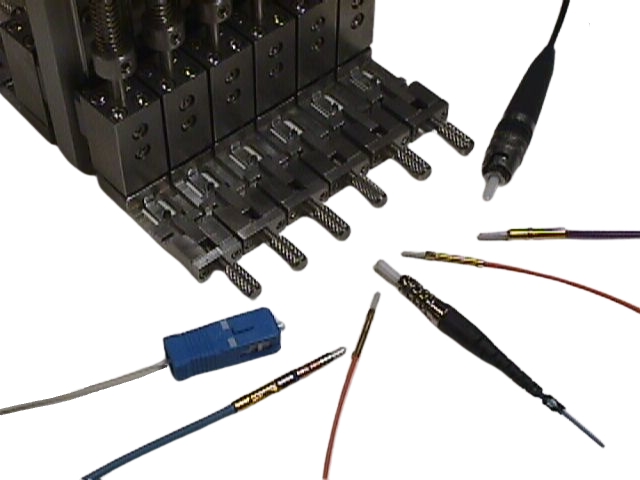

Universal Connector Fixtures

KrellTech’s unique Universal Workholder supports all UPC connectors, ferrules, and Mil-spec termini in a single polishing jig. Components supported include SC, FC, ST, LC, MU, E2000, SMA 905, SMA906, M29504, LuxCis, ARINC 801, ELIO, MC5, RSC and many others.

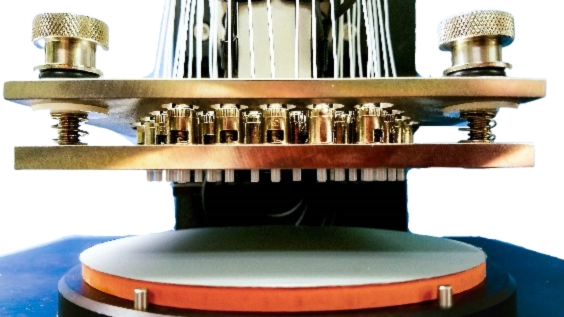

High Capacity UPC Connector Workholders

Maximize production through-put with KrellTech's HiCap Workholders. Up to 28 UPC connectors can be quickly loaded and processed at a rate of 6 connector per second. An integrated pressure control mechanism guarantees positive contact across all connector endfaces.

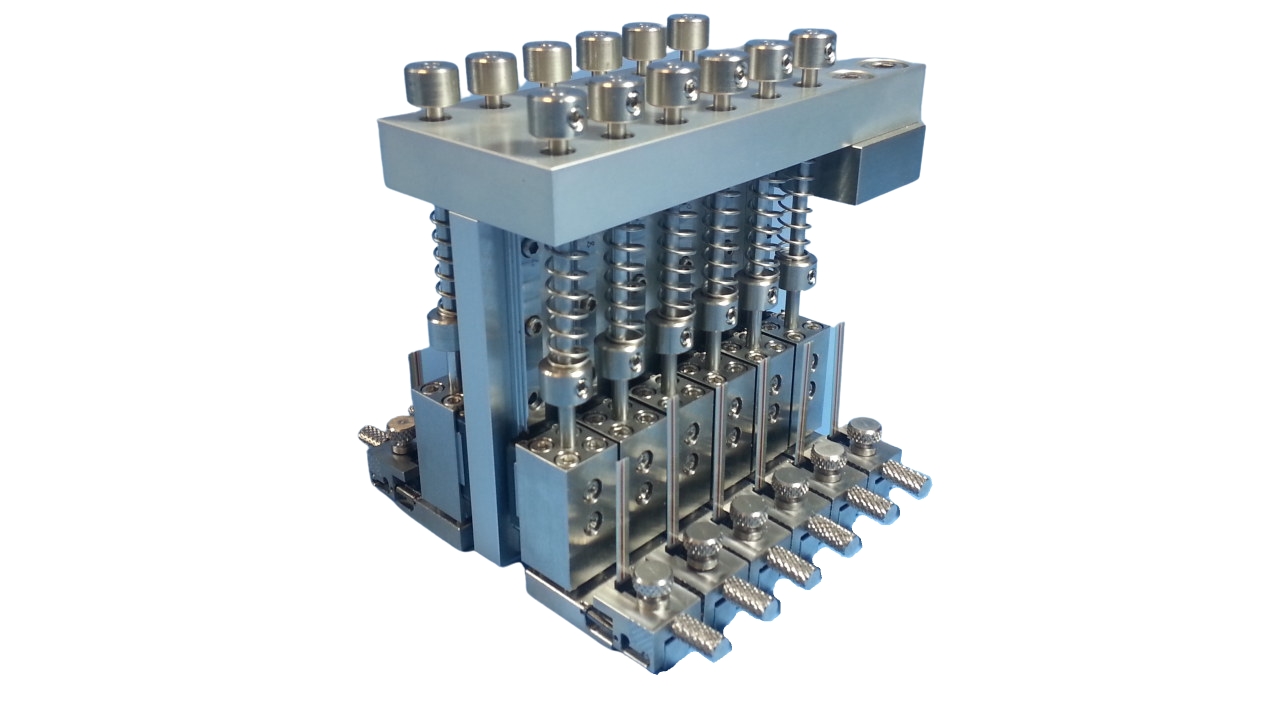

Multi-Fiber Connector Fixtures

These fixtures are designed to meet the stringent endface geometries such as flatness and fiber protrusion required for multi-fiber ferrules. Connectors supported include MT, MTP, MTO, MTx and MT-RJ. Both UPC and angled fixture are available. Fixtures also available to support MMC connectors with TMT ferrules. All fixtures feature fast and positive "tool-less" ferrule loading. Simply (1) retract the clamp, (2) insert ferrule and (3) lock the clamp. Like all Krell workholders these fixtures feature independent suspension for equalized pressure distribution and optical aligned ferrule holders for superior endface geometry control.

Plastic Optical Fiber Workholder

Plastic optical fiber (POF) workkholders can polish over 500 fibers in less than 5 minutes. Adaptable bushing design can accommodate a large variety of fiber diameters. This fixture also features Krell's patented independent suspension design for superior pressure control.

Industry Standard and Custom Polishing Fixtures

Workholders are available for all industry standard optical connectors. These include SC, FC, ST, LC and many others. Both UPC and APC endface geometries are supported. Adapters can also be used for bare fiber polishing in these fixtures. KrellTech’s engineering team develops customized polishing equipment for all applications and optical requirements. We have designed fixtures for products ranging from cannula and illumination bundles, to waveguides and fiber arrays. When requesting a quotation please provide detailed application specifications and attach all relevant drawings and information.

Image captions, left to right:

- Polishing workholder for medical cannula.

- Polish all 2.5mm connectors and ferrules with this fixture.

- Polishing fixture supports all ferrules 1mm to 3.2mm UPC geometry.

- AVAGO HFBR-4531 and 4532Z.

- Biconic connector jig with length control.

- High power connector polishing fixture.

- Adjustable, large diameter bare fiber LD workholder.

- Standard FC/APC 8 degee workholder fixture.

- FlexGrip workholder for large and odd-shaped components.

- Glenair GHD APC fiber optic termini.

- Bulkhead fiber optic connectors.

- M29504 termini with short breakout.

- Glass ferrule with angle polished endface.

- Universal APC workholder with angled v-groove.

- Universal angled polishing fixture.

- Glass slide polishing.

- Glass die

- Micro glass blocks

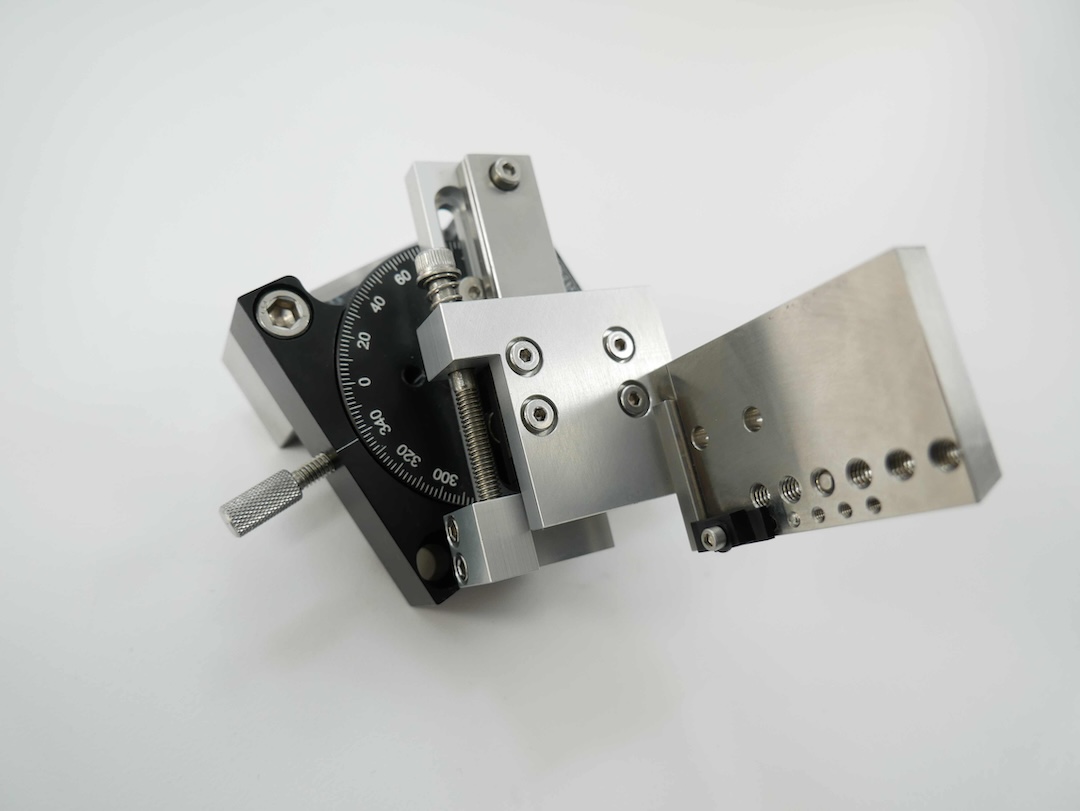

NOVA™ Workholder for PICs/Waveguides, Fiber Arrays, and Optical Chips

The NOVA™ Workholder is designed for precise polishing and shaping of photonic components, including waveguides, fiber arrays, and optical chips. It ensures high-quality finishes and repeatable results, making it an essential tool for photonic component production.

Key Features:

Adjustable Polishing Angles: 0° to 45° for flexible processing.

Component Size Compatibility:

- Standard: 3mm to 25mm edge width

- Extended Length Model: Up to 50mm

- Supports thicknesses from ~0.5mm to <5mm

Workholder Options:

- Single-Position Variable Angle (manual or automated)

- Four-Position Variable Angle (manual)

- Eight-Position Fixed Angle

PIC & Waveguide Carriers:

- Ergonomic and repeatable mounting

- Seamless integration with NV-FLEX and NV-FLEX-A fixtures for optimal polishing

The NOVA™ Workholder provides the precision and flexibility needed for photonic manufacturing, ensuring consistent edge preparation and polishing for PICs, optical chips, and fiber arrays.