INSPECTION SYSTEMS

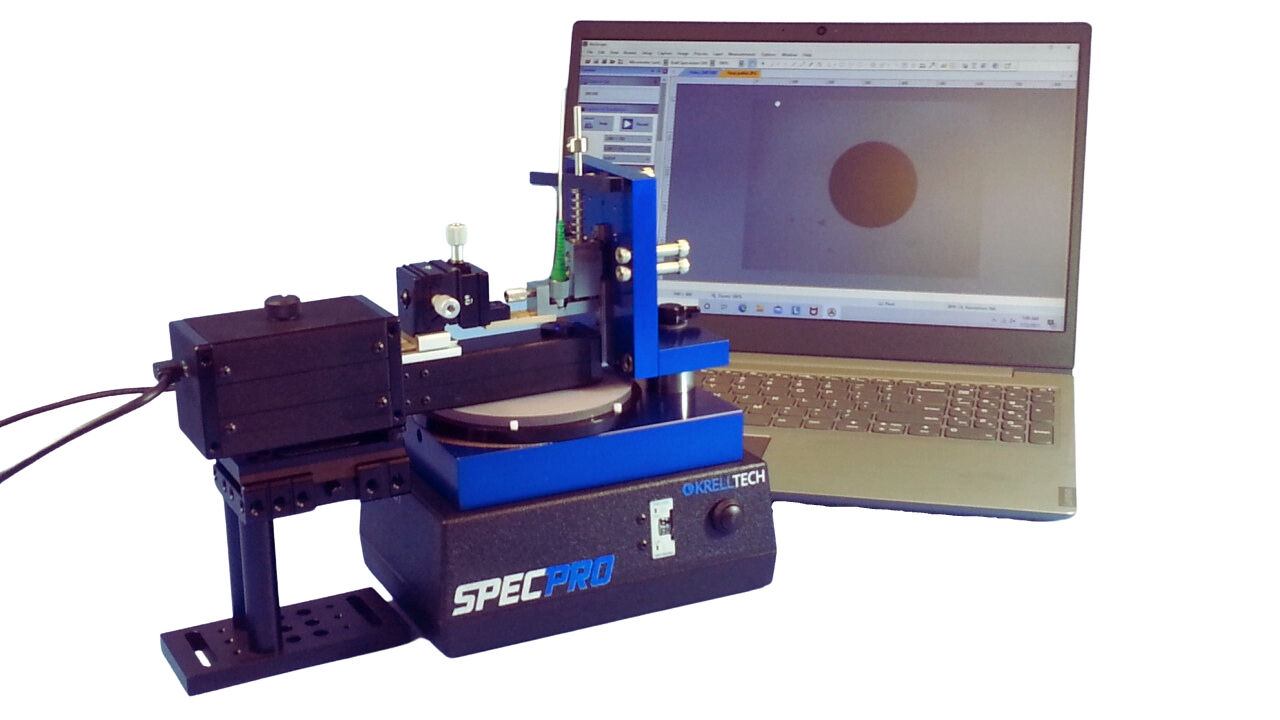

SpecVision™ Video Inspection Scope

SpecVision™ is a video probe and fiberscope that engages directly with Krell polishing machines. This permits the viewing of polished optical surfaces while connectors or bare fibers are still loaded in the polisher. This in-line video inspection technique minimizes material handling and potential damage/contamination that may occur when transferring components from the polisher to a traditional microscope. SpecVision™ can interface with Scepter™, NOVA™, SpecPro™ and Rev™ Polishers.

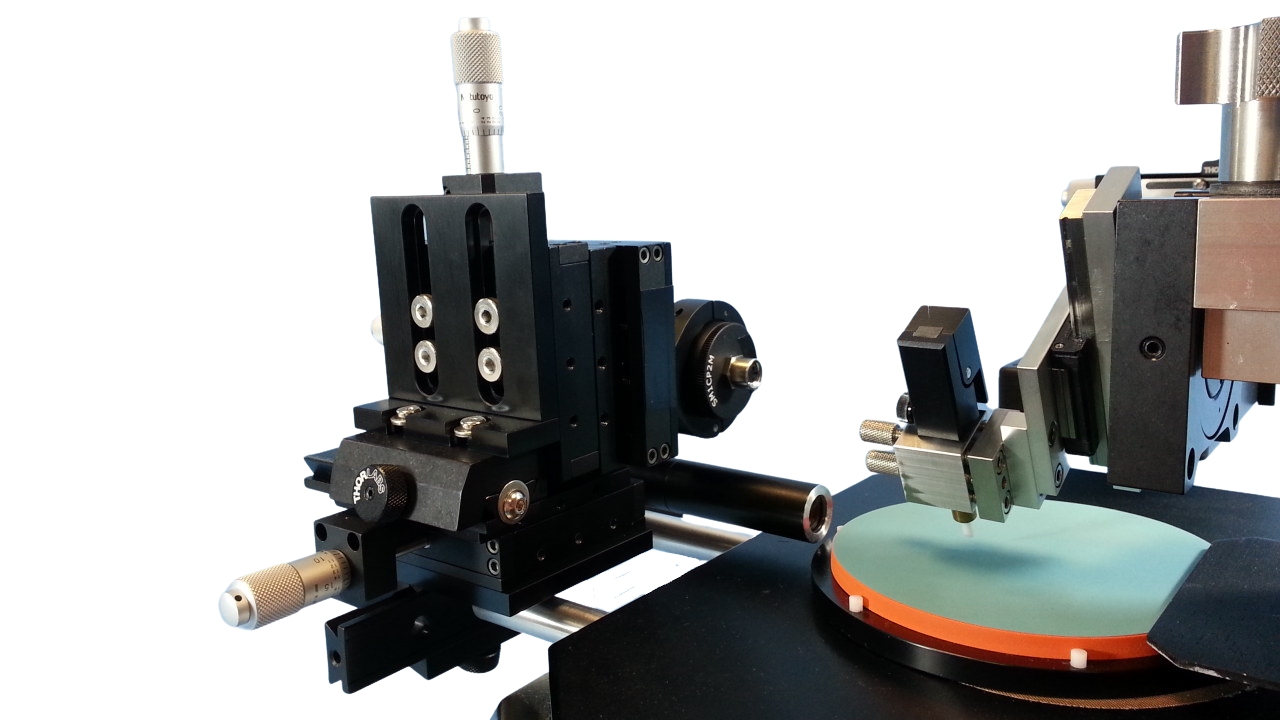

NOVA™ Profile Inspection Module

NOVA™'s Profile Videoscope allows the real-time monitoring of component polishing. This videoscope aids with bare fiber/component positioning and confirms process completion. Teamed with measurement software, this system verifies the endface geometry of fibers, waveguides and arrays.

NOVA™ Surface Inspection Module

NOVA™'s Surface Videoscope allows the in-line inspection of polished surfaces while the component is still loaded in the polisher. This minimizes material handling and streamlines photonic production compared to the traditional process of transfering components to off-line inspection stations. Polishing and specification compliance can be determined in a single workcell.

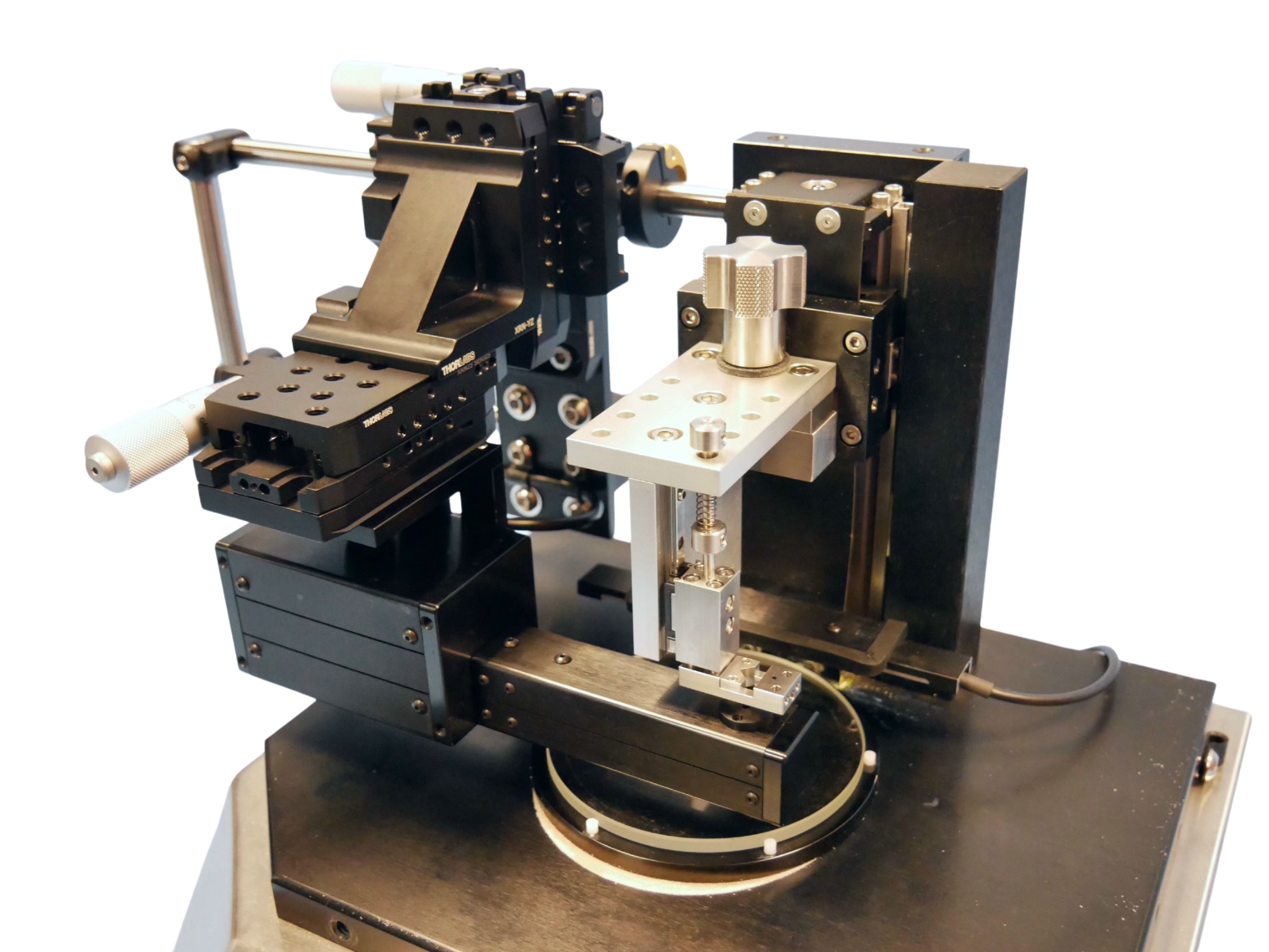

InSight™ In-line Video Inspection Station

InSight™ In-line Video Inspection Station is a dedicated video station for the inspection of fiber optic connectors and photonic components. All Krell polishing workholder fixtures can quickly engage with this system allowing in-line inspection without the need to remove the connector/termini/chip/component from the polishing fixture. This streamlines quality assurance and minimizes the change of component damage and contamination that can occur when removing and transfer parts back-and-forth between polisher and microscope. Magnification levels can easily be change by the simple exchange of optical objectives. InSight™ supports NOVA™, Scepter™, SpecPro™, FLex™, Radian™ and Proton polishing equipment and machines.