WAVEGUIDE & ARRAY

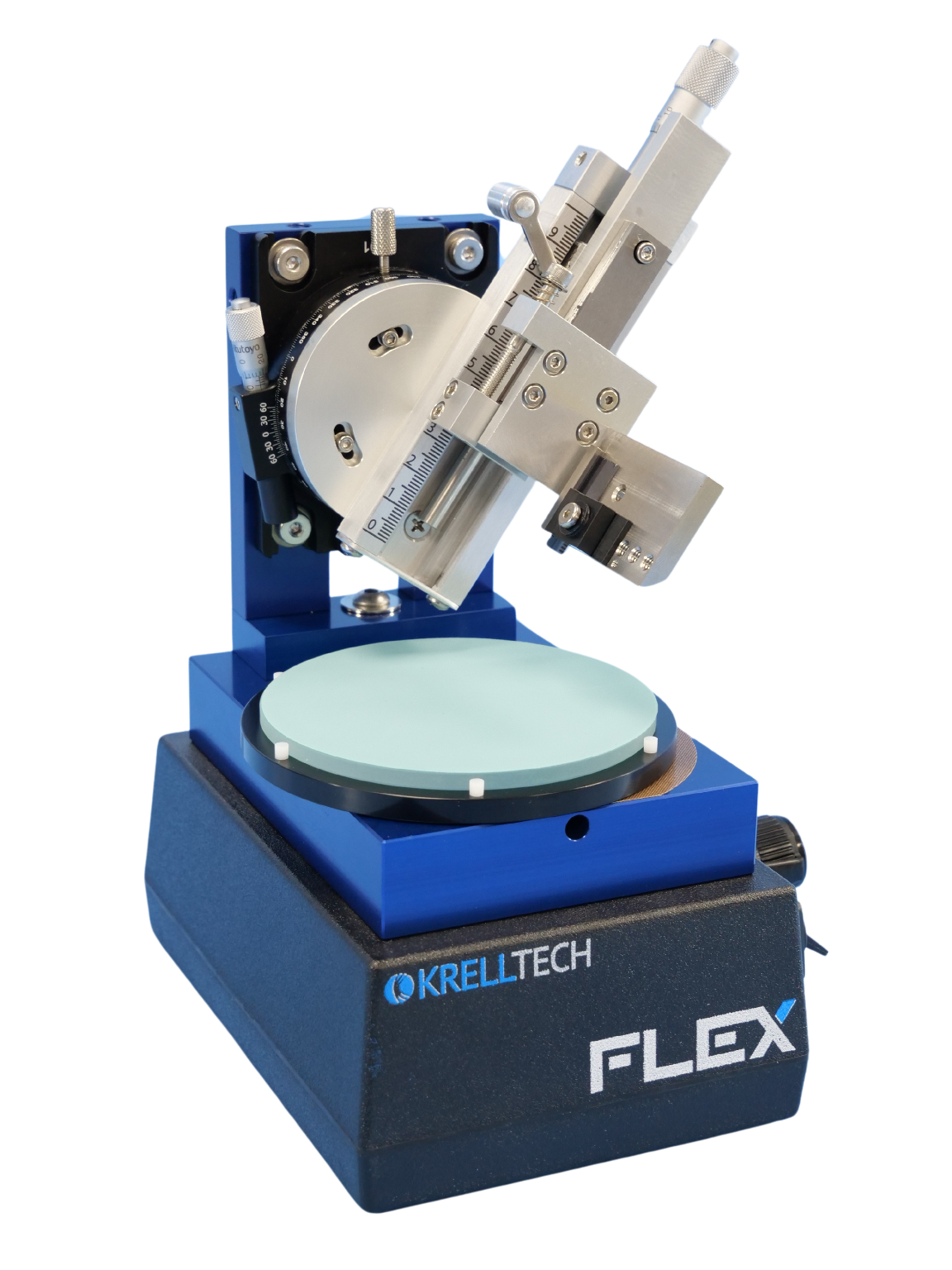

NOVA GEO™ PIC Waveguide & Array Polishing System

NOVA GEO™'s flexible processing platform allows it to be configured for polishing waveguides, PIC optical chips, PLCs and fiber arrays. Polished endface angles can be varied from 0 to 50 degrees using either manual or automated workholder stages. GEO™'s component mounting plate is adjustable for varying edge widths and thickness.

Optional video inspection systems monitor the polishing process and inspect the polished surface directly in GEO™. In-line viewing minimizes material handling and is a means to confirm endface geometry before removing the component from the machine.