Photonic Processing Equipment That Scales: A Lightning Talk by Al Cheswick

Release, July 22, 2025, 8:03 p.m.

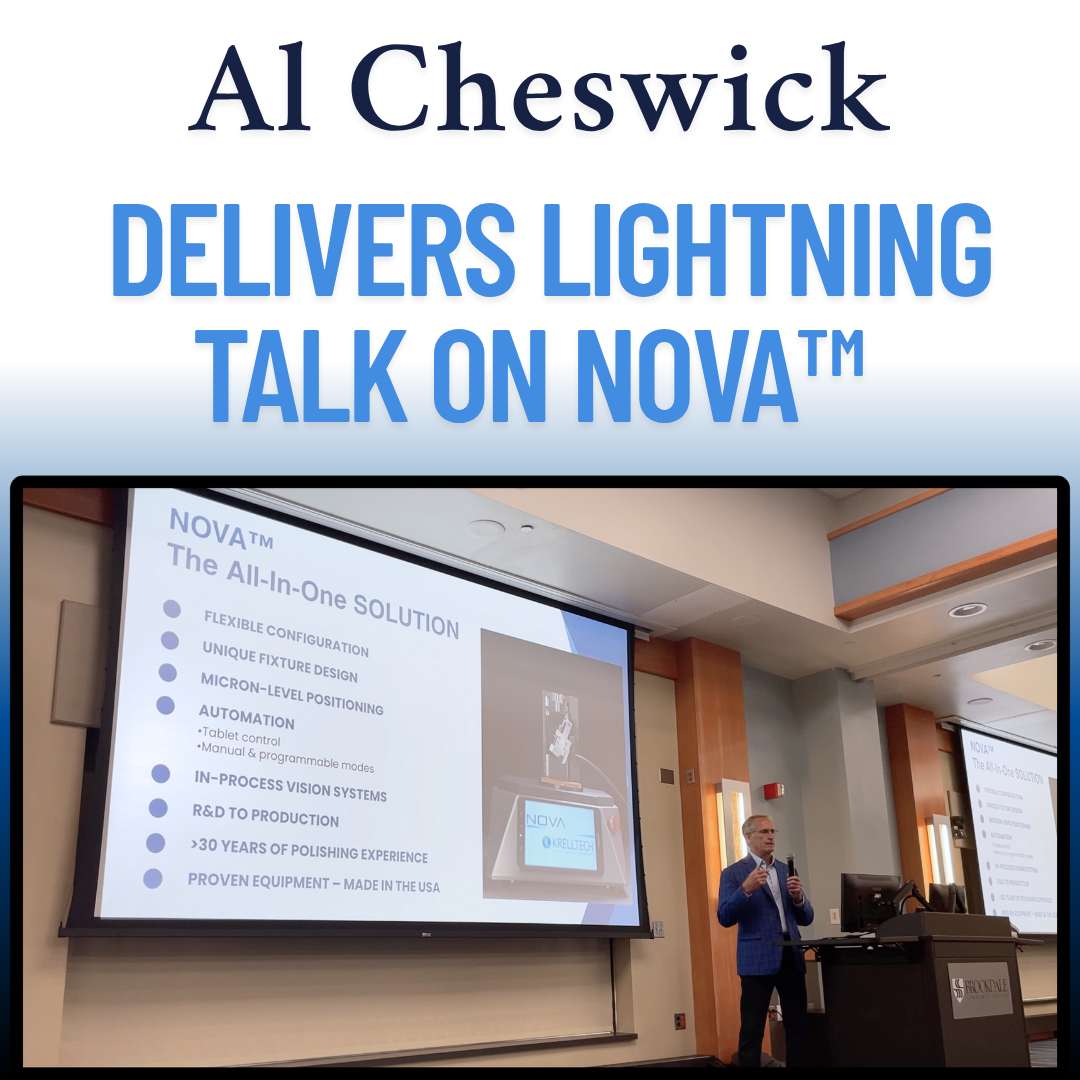

At a recent PhotonicsNJ gathering, Al Cheswick, President of Krell Technologies, delivered a Lightning Talk that distilled over three decades of experience in photonic component processing into a powerful, real-world overview. His message? Polishing might not be glamorous, but it’s essential.

KrellTech, based in Neptune City, NJ, designs and manufactures photonic processing equipment used to shape, polish, and inspect fiber optic components and photonic integrated circuits (PICs). These systems are built for both R&D labs and high-volume production lines, ensuring precise, reliable results at every stage.

“We do the nitty-gritty part of the optics business,” Al shared. “It’s not quantum computing or photon entanglement, it’s the core work of shaping materials and ensuring their quality.”

During the talk, Al outlined a wide range of applications and challenges KrellTech systems are designed to address:

- Connector polishing with automation and intermateability in mind

- Bare fiber shaping with micron-level facet control

- Medical and sensing probe customization

- And the increasing demands of PIC polishing, where length control, material removal, and in-process inspection are critical

Central to KrellTech’s solution is NOVA™, their all-in-one platform that combines:

- Interchangeable fixtures for diverse applications

- Micron-level positioning for accuracy

- Vision systems for real-time inspection

- Tablet-based automation for user-friendly operation

- Over 30 years of process knowledge baked into the platform

With NOVA™, you're not polishing blind. You're polishing with precision, visibility, and adaptability.

Watch the full presentation here: https://krelltech.com/videos/watch/photonic-processing-equipment/

Full Transcript:

0:35

Hello.

0:36

My name is Al Cheswick, president of Krell Technologies.

0:53

We're based in Neptune City, NJ and what we do is we design and we manufacture photonic processing equipment.

1:01

We can pretty much sum up what we do in kind of three words.

1:07

We shape, Polish and inspect photonic components and fiber optic devices.

1:14

Basically kind of like the nitty gritty part of the optics business, because what we're doing is really grinding material.

1:21

So it's not like the sexiest thing like quantum computing or photon entanglement.

1:26

It's like basic polishing and inspection of items.

1:32

So what I'm going to do is really quickly give an overview of the applications that we address and the design challenges of the equipment to address the proper processing of different materials.

1:50

First thing was a connector polishing.

1:52

Since first fibers were put in telecommunication network, there was always a need to join fibers and to have low loss and low reflectance joints basically.

2:04

So what would develop were connectors and over the years have been a many, many different style connectors for this type of purpose, dozens of them actually.

2:14

So when you're choosing a piece of processing equipment, you have to find one that is adaptable to all these different types of components and they change all the time.

2:24

Every year there's a new type of component that comes out.

2:27

And since they're connectors and they're commercially available, there's issues of intermateability between other vendors.

2:34

So industry standards have been developed such as Telcordia and IEEE and Mil Specs that any equipment that you develop, the product that comes out of it complies with the specifications and the requirements of those standards.

2:51

And also in connector polishing automation is key to because you want to have low level technicians being able to operate the equipment properly in production lines.

3:04

And over the years fiber has gone from telecom and datacom into many other applications have discussed already including medical sensing laboratory.

3:16

And with this, there's been developments and different types of probes and devices, Endoscopes, catheters, different types of OCT probes in sensing vibrations, structural sensing, fiber optic, gyroscopes.

3:35

All these are usually customized devices, unlike the connectors that are specific to 1 manufacturer.

3:42

Hence, any type of polishing equipment that you develop has to be adaptable and customized for those in particular purposes.

3:51

And with that customization often comes intensive process development from project to project.

4:01

And not all connectors are, not all bare fibers are connectorized.

4:05

In many situations, you want to Polish the bare fiber itself.

4:09

In this case, you can see we're doing an example of a 125 Micron fiber and we're able to put various facets on it.

4:16

And depending upon the shape, basically the shape of the end of the tip of the fiber gives you the ability to manipulate the light.

4:23

And here in these situations, the challenge is basically with processing equipment is the wide variety of types of fibers that are available nowadays.

4:31

It's not just standard telecom 125 micro fiber.

4:35

Now you have PM fiber, you have photonic crystal fibers, you have sapphire fibers and you also have a wide range of dimensions.

4:44

All these have to be supported by adapters in these machines and also taken into consideration the delicate nature of the fibers so that they do not break into the processing.

5:01

The newest application we've been involved with over the last five or six years is photonic integrated circuits, or PICs, which as you most of you know, are basically chips that have wave guides embedded in.

5:13

These have represented new processing bands where material removal has to be controlled.

5:19

Length control is critical and you have to be able to monitor their process very closely and make measurements on all these.

5:28

What we've done with our equipment, we've developed a system called NOVA, which is what we are all-in-one solution that addresses all these applications and the considerations that have to be applied.

5:40

So we have interchangeable fixtures for either connector polishing, fiber polishing, PIC polishing probe, any type of adapters.

5:49

We use micron level positioning for length control.

5:53

We have it automated with a standard tablet and familiar Android interface.

5:59

For easy operation.

6:01

We have manual programmable modes.

6:03

Manual modes are used to develop processes and those parameters then can be transferred program modes.

6:11

And with NOVA, you're not polishing blind.

6:13

We have vision systems that allow you to monitor the polishing process in real time and also inspect the quality of the specimens that are being polished while they're still in the machine, making it basically a work cell approach.

6:27

We've been in business for over 30 years.

6:29

We've had a proven track record of making high quality machines and unique machines and we also have a very extensive database of processing.

6:38

So when equipment is purchased from us, you're not just getting a machine, you're also getting knowledge support from many years.

6:48

Any questions?

6:55

Thank you.

6:56

Any questions?