1

2

3

4

5

6

7

8

9

10

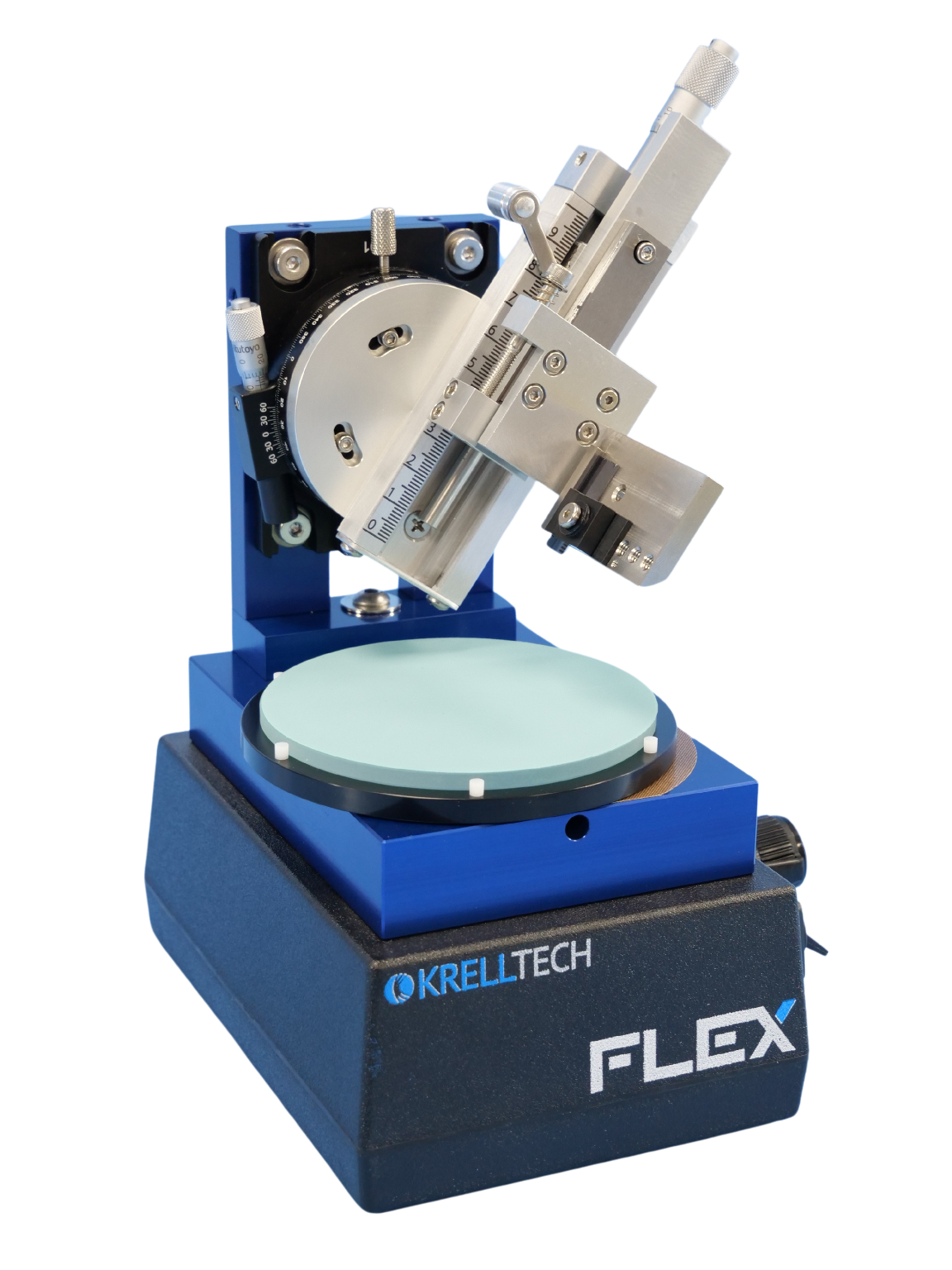

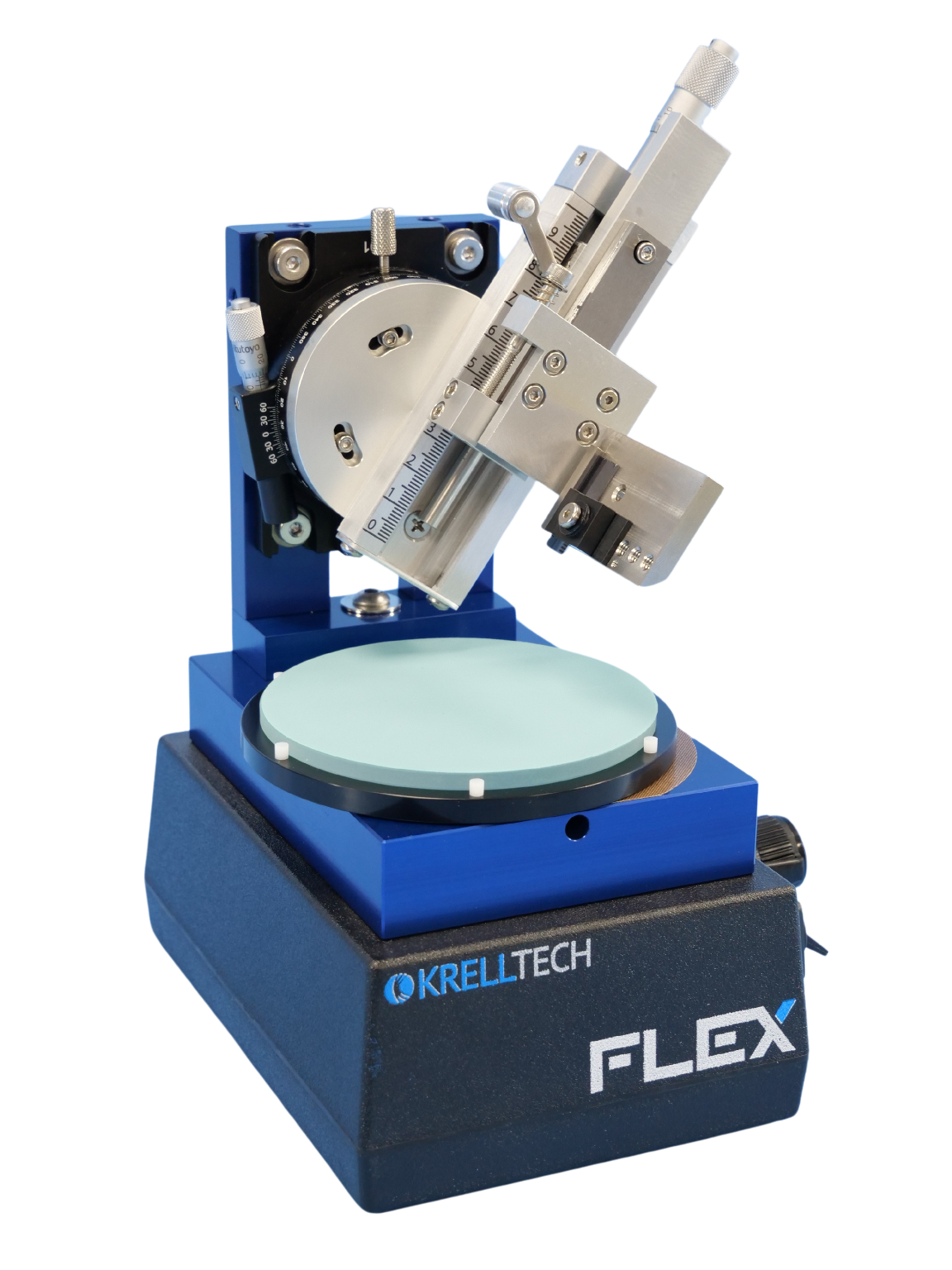

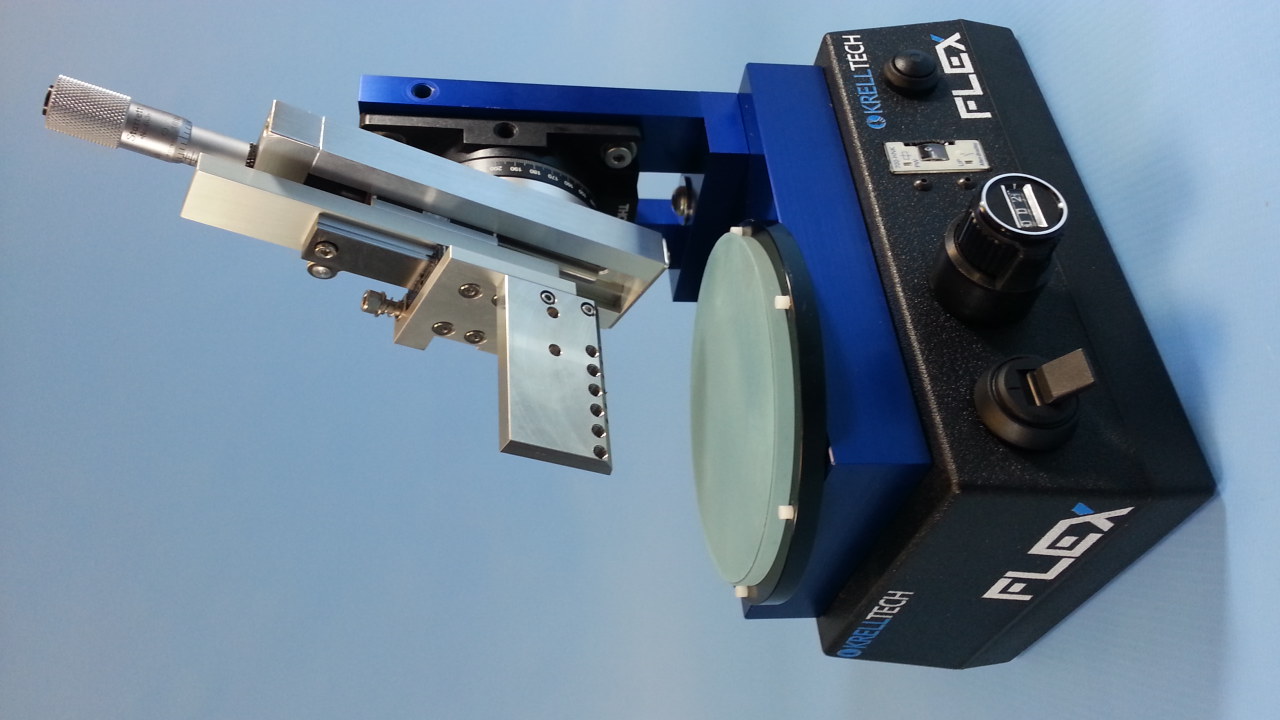

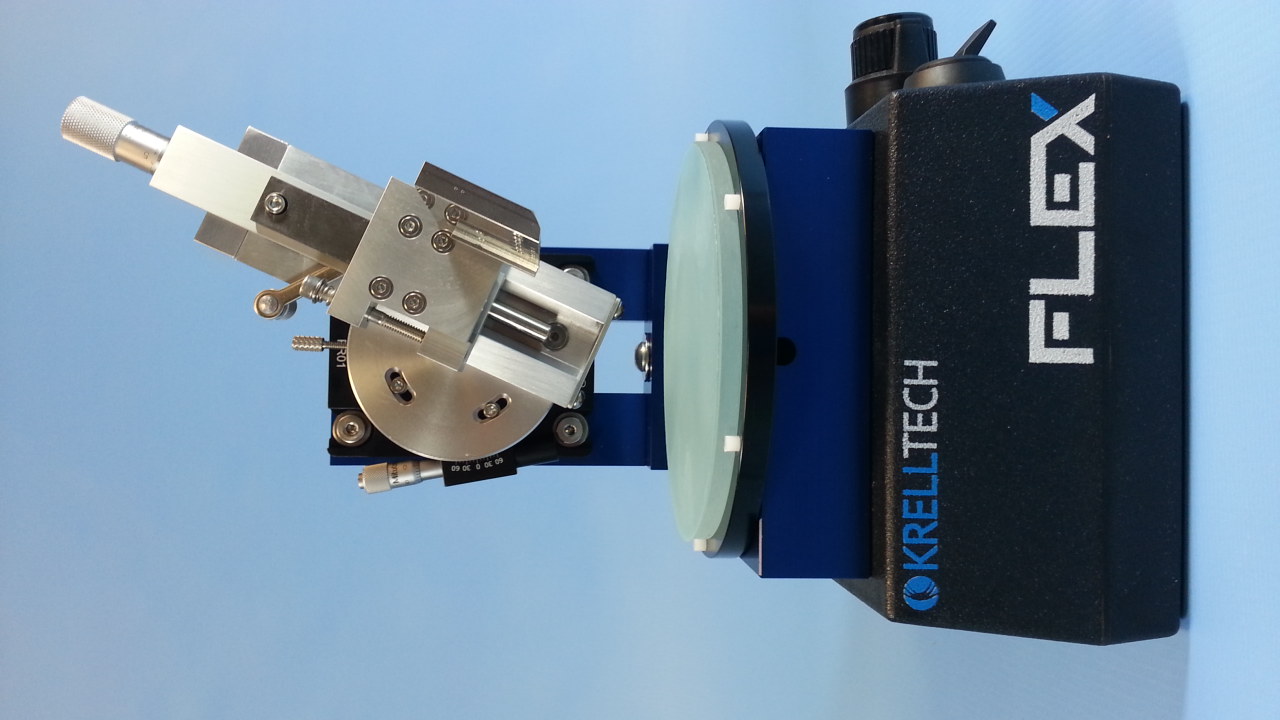

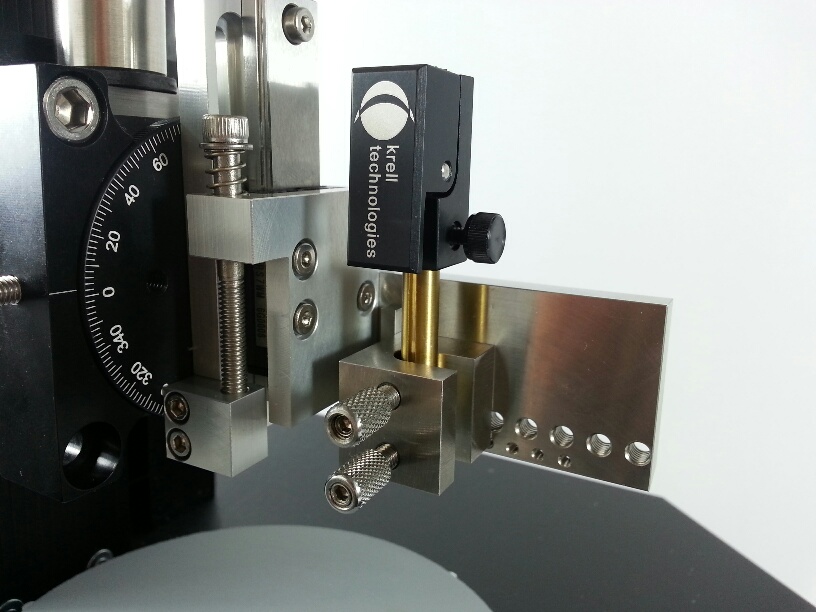

FLex PIC & Waveguide Polisher

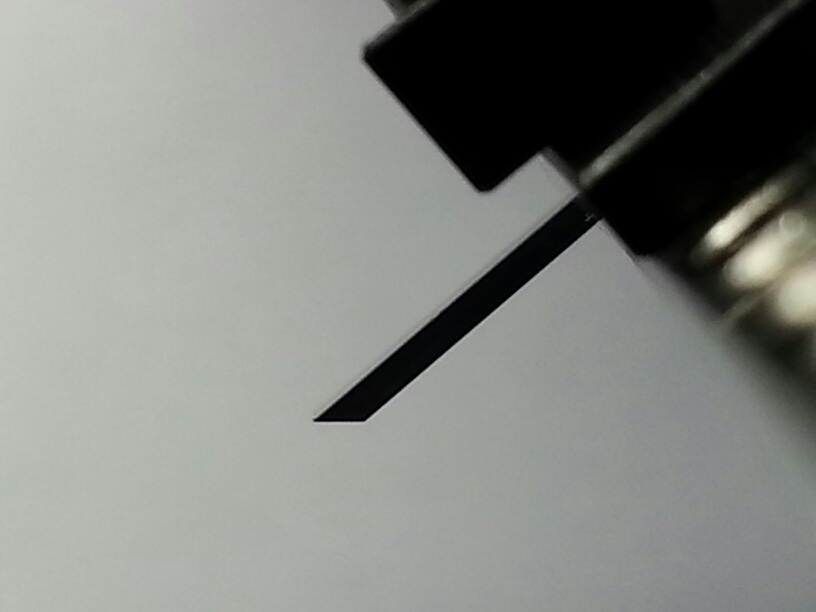

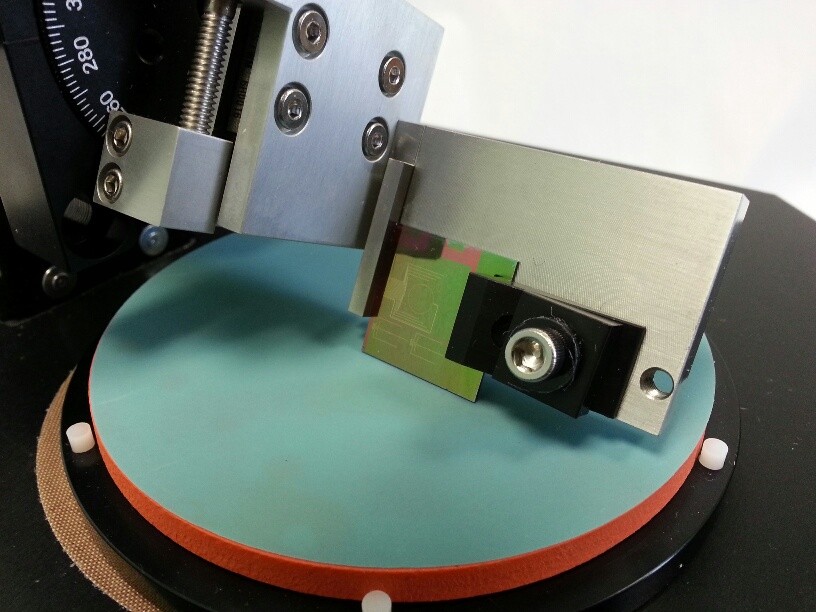

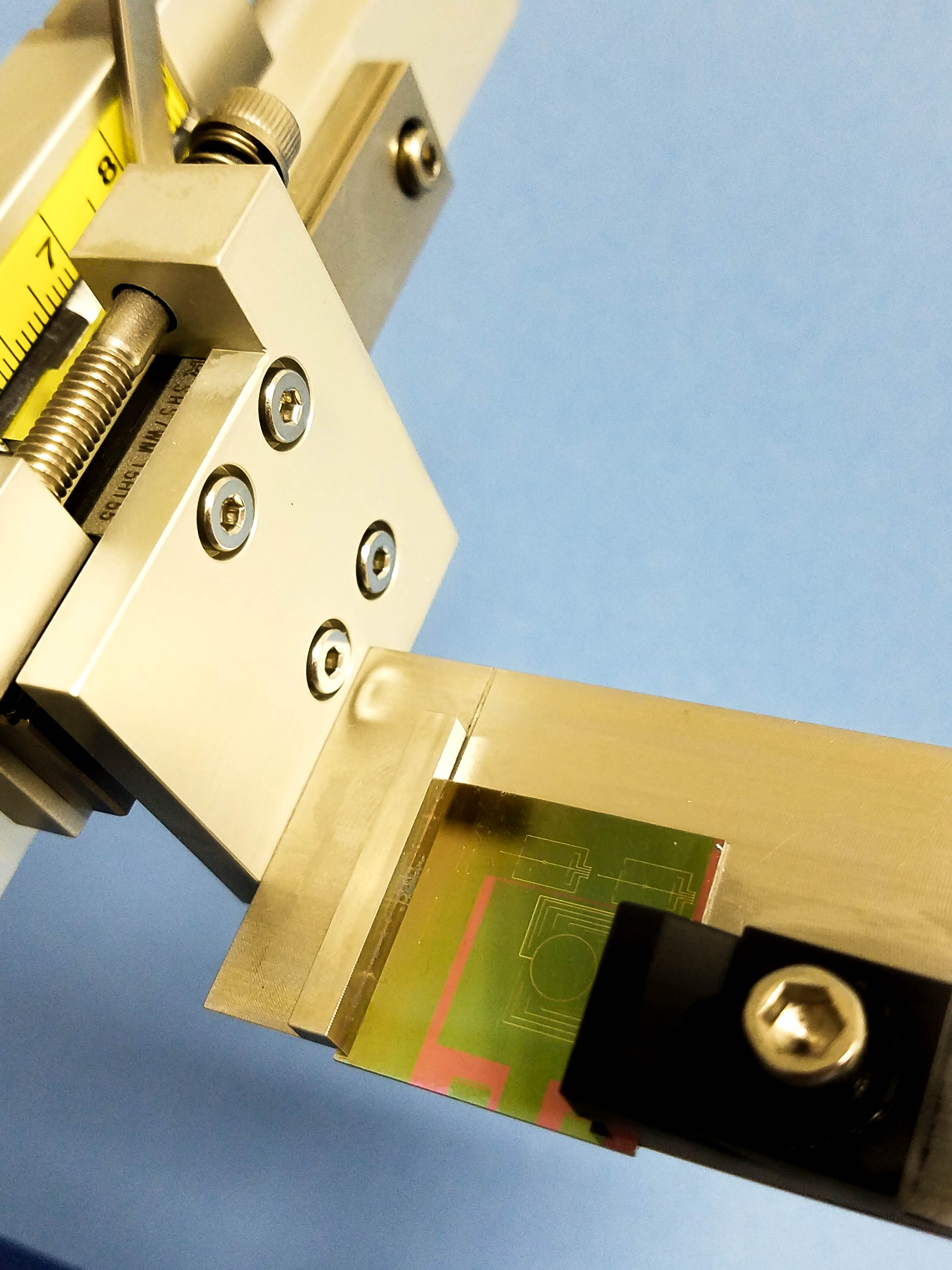

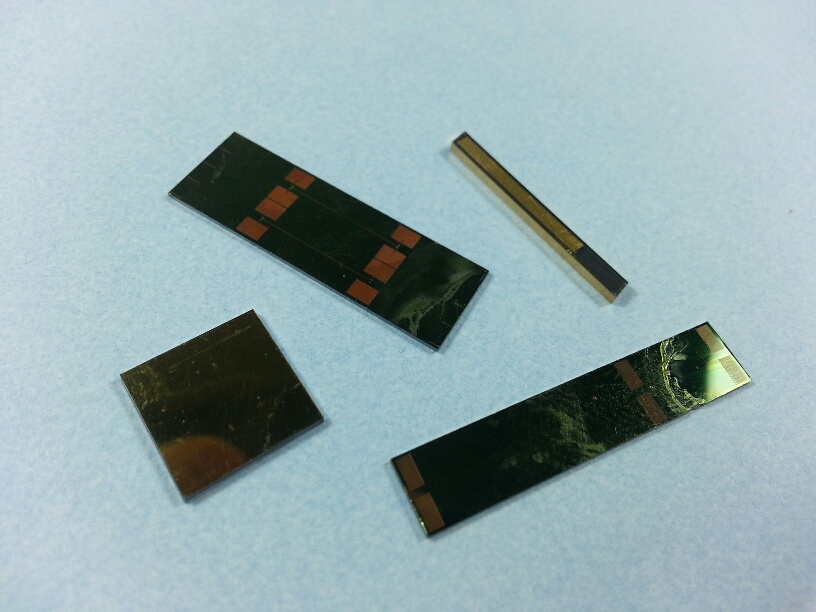

FLex is capable of polishing a variety of waveguide components such as PLCs, PIC optical chips and fiber arrays. It integrates universal carriers that can accommodate components of various dimensions, as well as the ability to polish at variable angles.

Starting at

$ 11,995

Related Q&A:

June 24, 2022, 6:41 p.m.

Q

Can this unit also polish FC connectors?

A

Accessories are available to convert the fixture to support FC connectors.

Sept. 21, 2020, 11:31 p.m.

Q

Hello,

We are interesting in a polisher but would like to run DI water while polishing. Is this OK to use water with these polishers?

A

Depending upon the particular application, an individual polishing step may be processed either dry or with water. Water tends to provide better surface finish when used on the final step. Just a couple light sprays of water on the film is sufficient.

April 3, 2020, 9:10 p.m.

Q

Is there a means to monitor the polishing process?

A

Real-time video monitoring is available with the NOVA system. Please view this product on our website.

March 24, 2020, 8:02 p.m.

Q

Is there an adapter that will convert this polisher into a bare fiber polisher?

A

Yes, our Bare Fiber Mount converts the waveguide fixture for bare fiber polishing.

Dec. 5, 2019, 9:11 p.m.

Q

Is video inspection available with FLex?

A

If you require video inspection of waveguides, NOVA will be required.