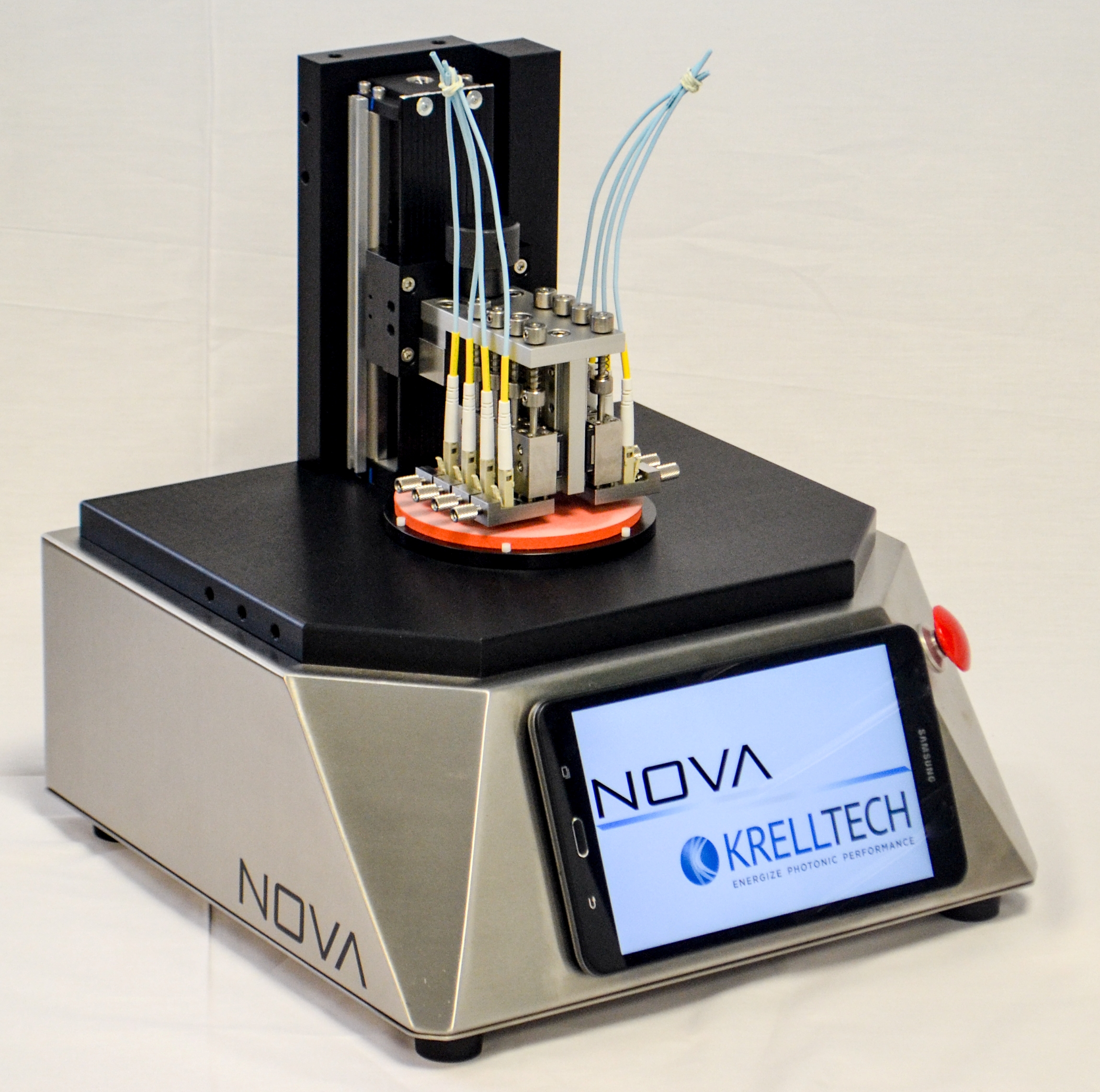

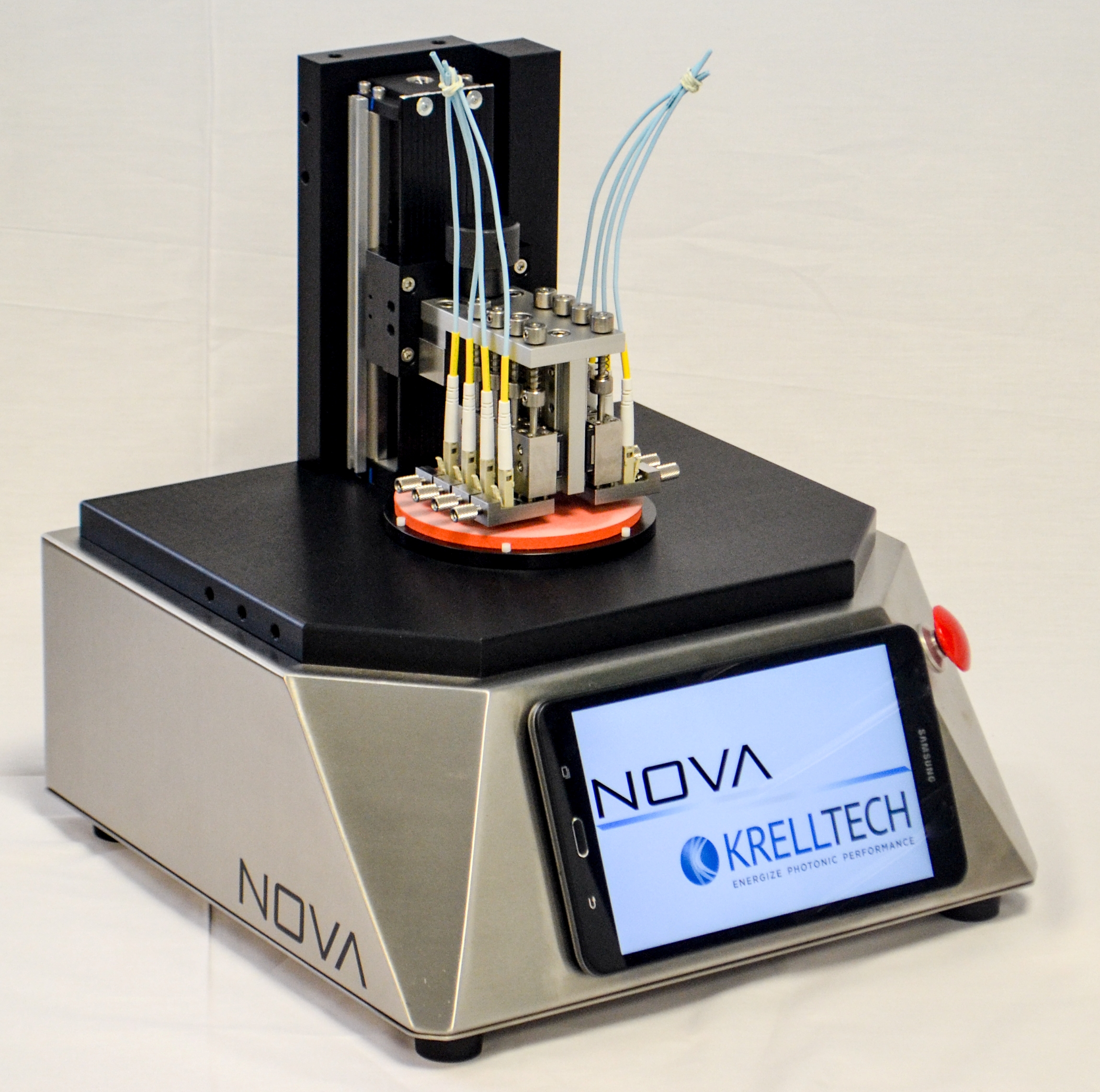

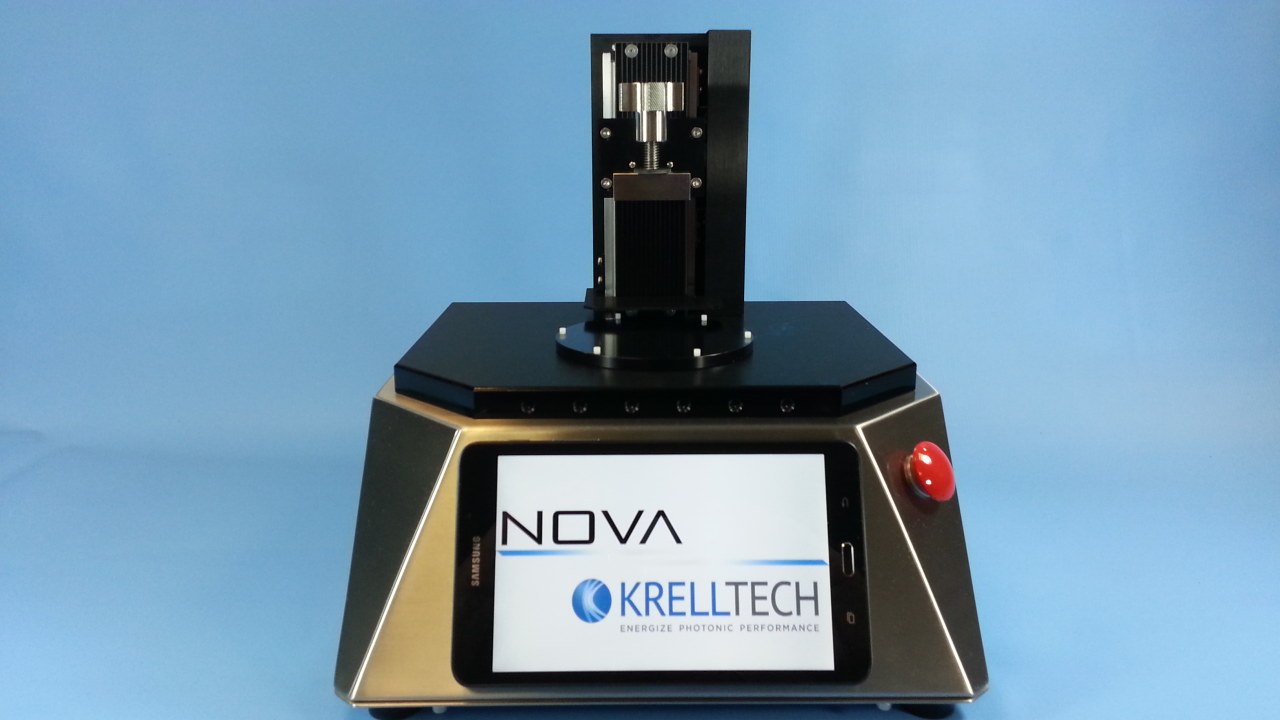

NOVA™

Automated & Multi-Configurable

Polishing System

PRECISION OPTICAL POLISHING

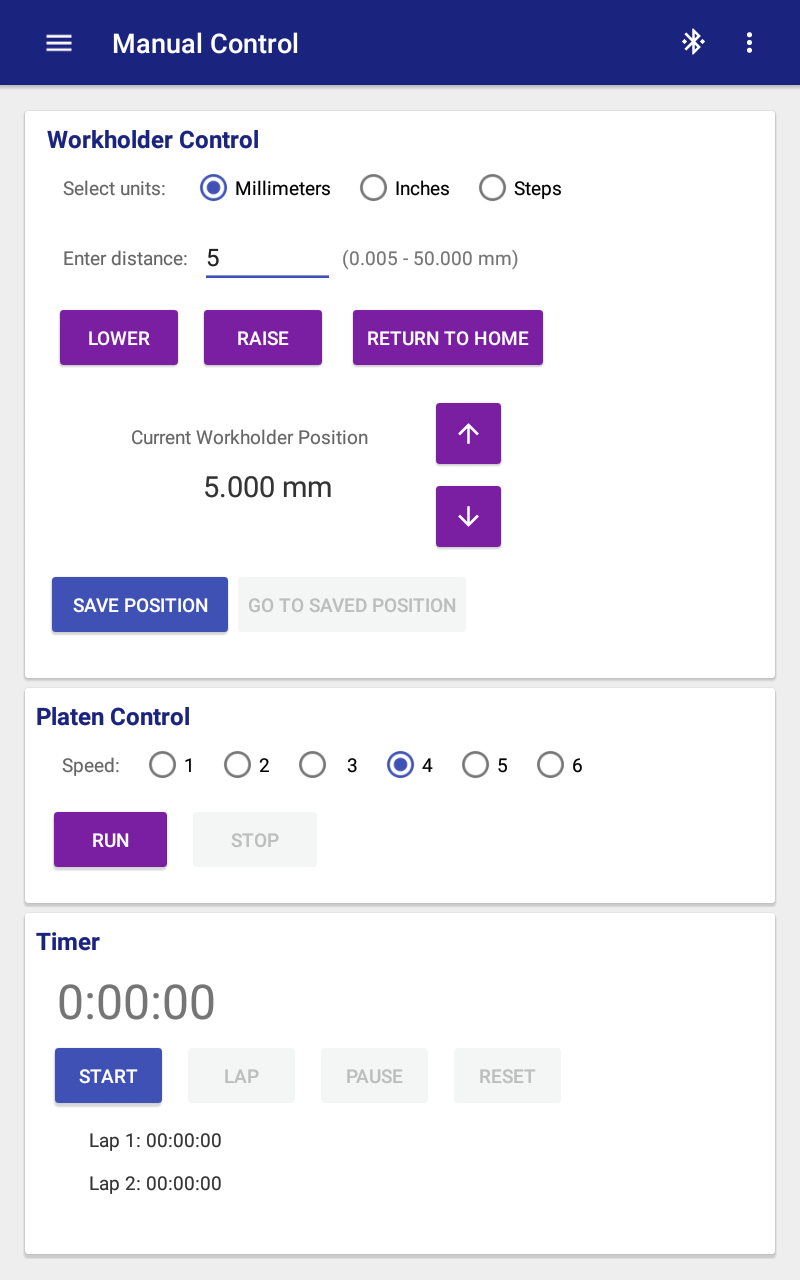

TABLET CONTROL WITH MICROFEED™

SUPPORTS ALL INDUSTRY STANDARD AND

CONNECTORS / MIL-TERMINI / FERRULES

AIR POLISHING IN MACHINE

TELCORDIA COMPLIANT

INTERCHANGEABLE FIXTURES FOR

WAVEGUIDES, BARE FIBERS AND MORE

Maximum flexibility for optical surface processing is now available with NOVA™. KrellTech has

integrated the proven performance and features of its industry leading Scepter, Trig and FLex

polishers into this configurable and cost-effective system.

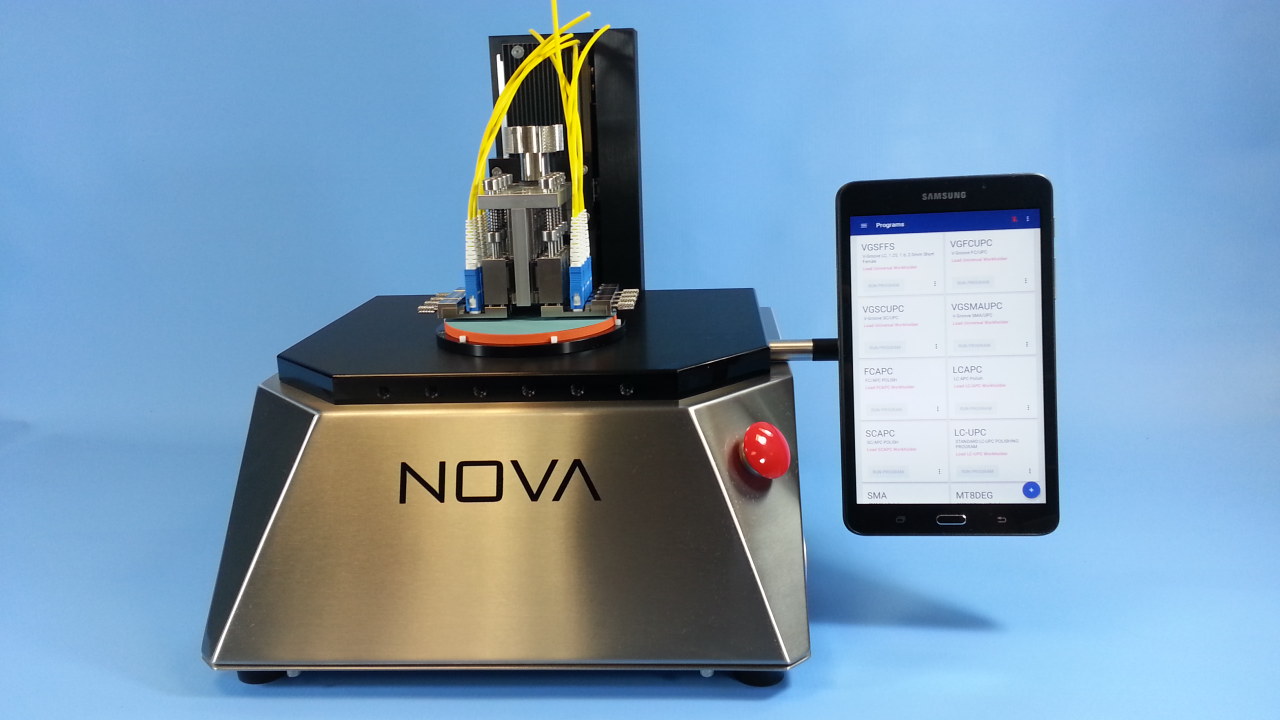

NOVA™ supports a variety of polishing applications from connectors to waveguides, and bare fibers

to custom components. NOVA™ is scalable for R&D projects, high volume production, and the rigors

of harsh environments and field installation.

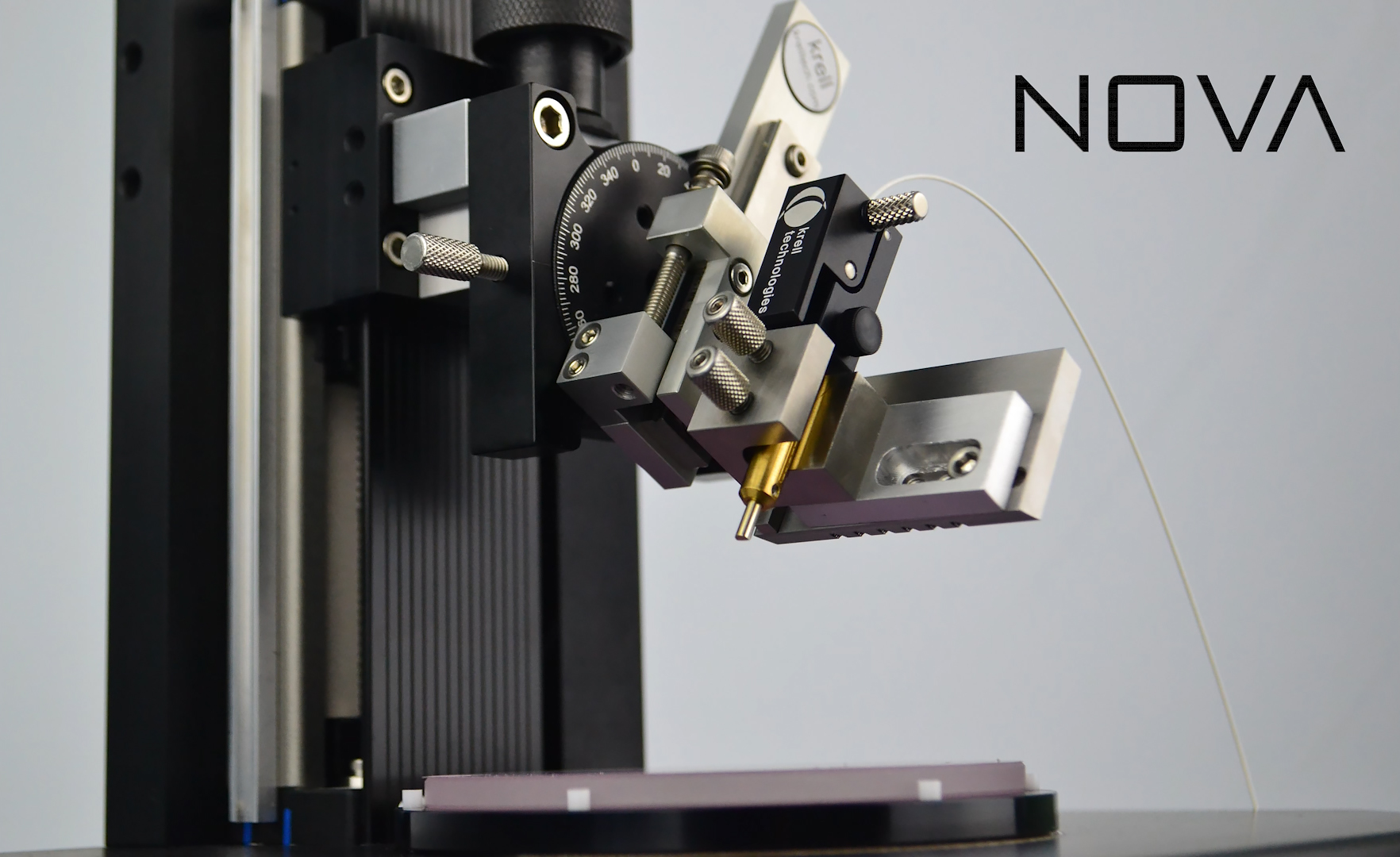

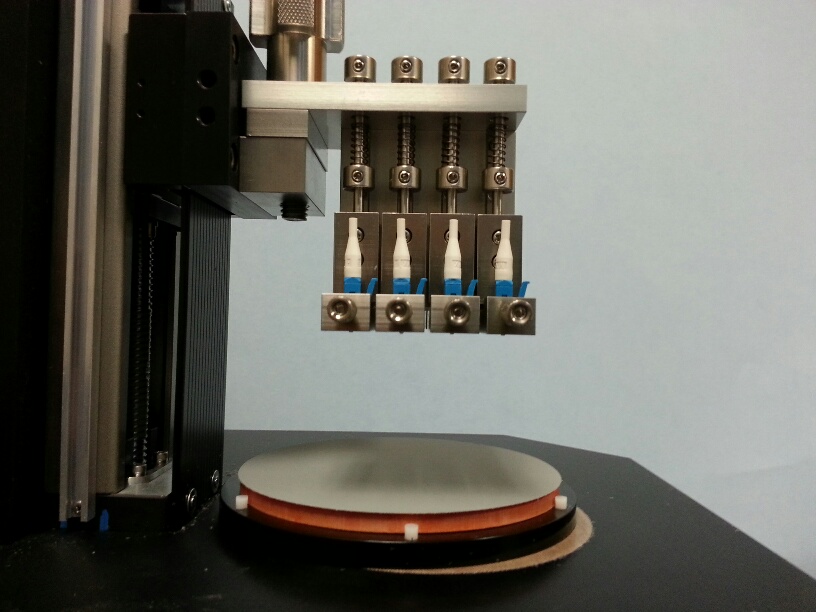

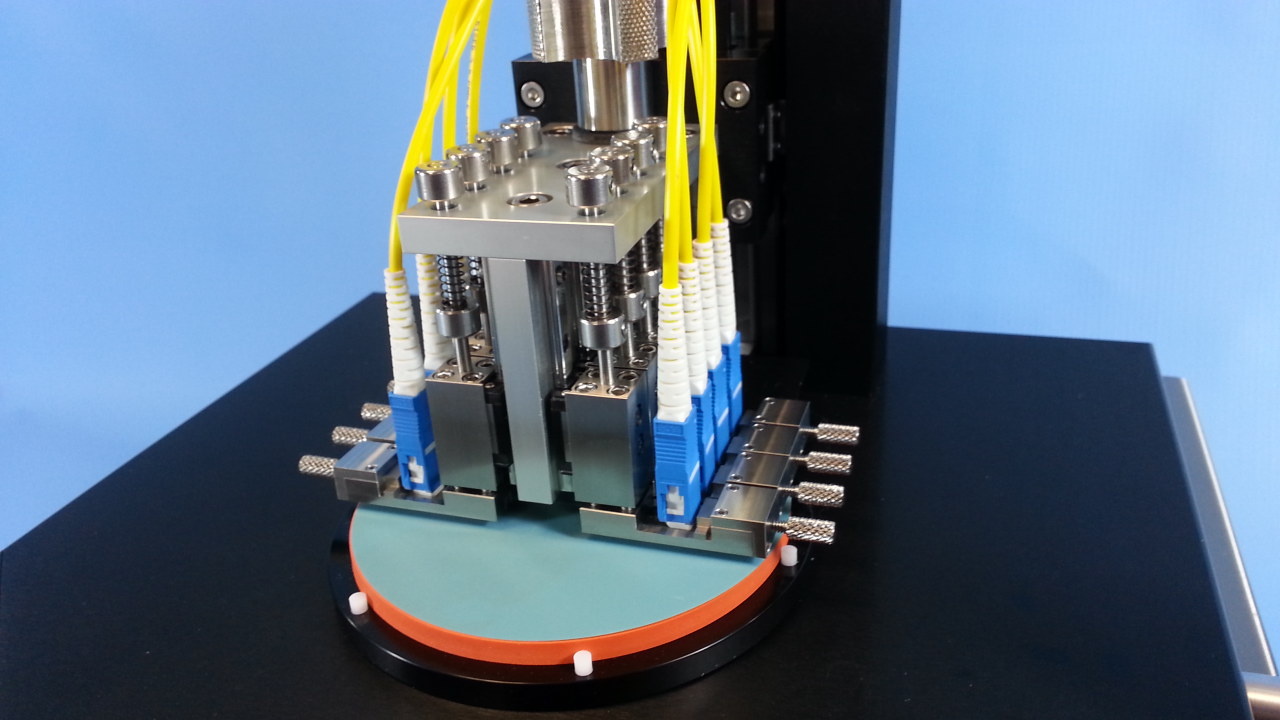

NOVA™ workholders feature NOVA’s versatility provides the Bare fiber can be polished at

KrellTech’s patented independent ability to support the polishing of variable angles using specialized

suspension at each connector many photonic components. A workholders and adapters.=

position for controlled pressure and quick change-out of workholder A variety of fiber types from

uniform contact. Combined with fixtures provides processing standard singlemode to PM, and

NOVA’s Microfeed™ fixture capability for waveguides, optical sapphire to PCF can be processed

advancement, connector “air- chips, PLCs, lenses and fiber into wedge and chisel tip shapes.

polishing” and epoxy removal can be arrays. A quick swap-out of adapters

performed directly in the machine. Workholders utilize a unique allow the polishing of fiber

Each position is optically aligned holding mechanism that can diameters from 80um to >3mm.

for optimal polish geometry using secure a wide range of Optional video inspection

KrellTech’s patented process and component dimensions. The systems monitor the polishing

calibration mechanism. Connector polishing angle is adjustable and process and inspect the polished

types can also be mixed and matched custom fixtures can be fabricated surface directly in NOVA.

in a single fixture. for specialized applications.

krell technologies, inc. · tel: (732) 775-7355 · sales@krelltech.com · www.krelltech.com

SPECIFICATIONS AND FEATURES

Operational

Controller1

Wireless tablet with Android

operating system

Polishing Pressure

Programmable & automated.

Linear displacement with micron

positioning control.

Polishing Speed

Program selectable

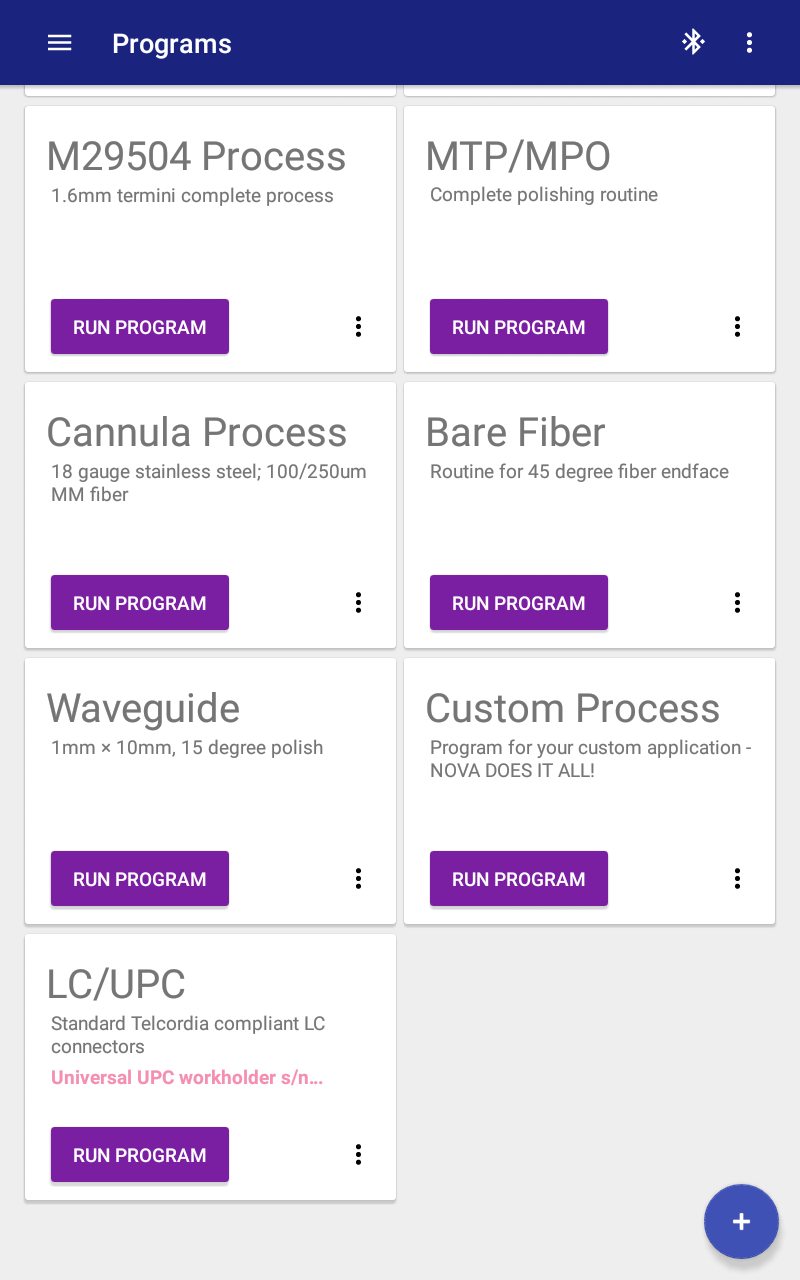

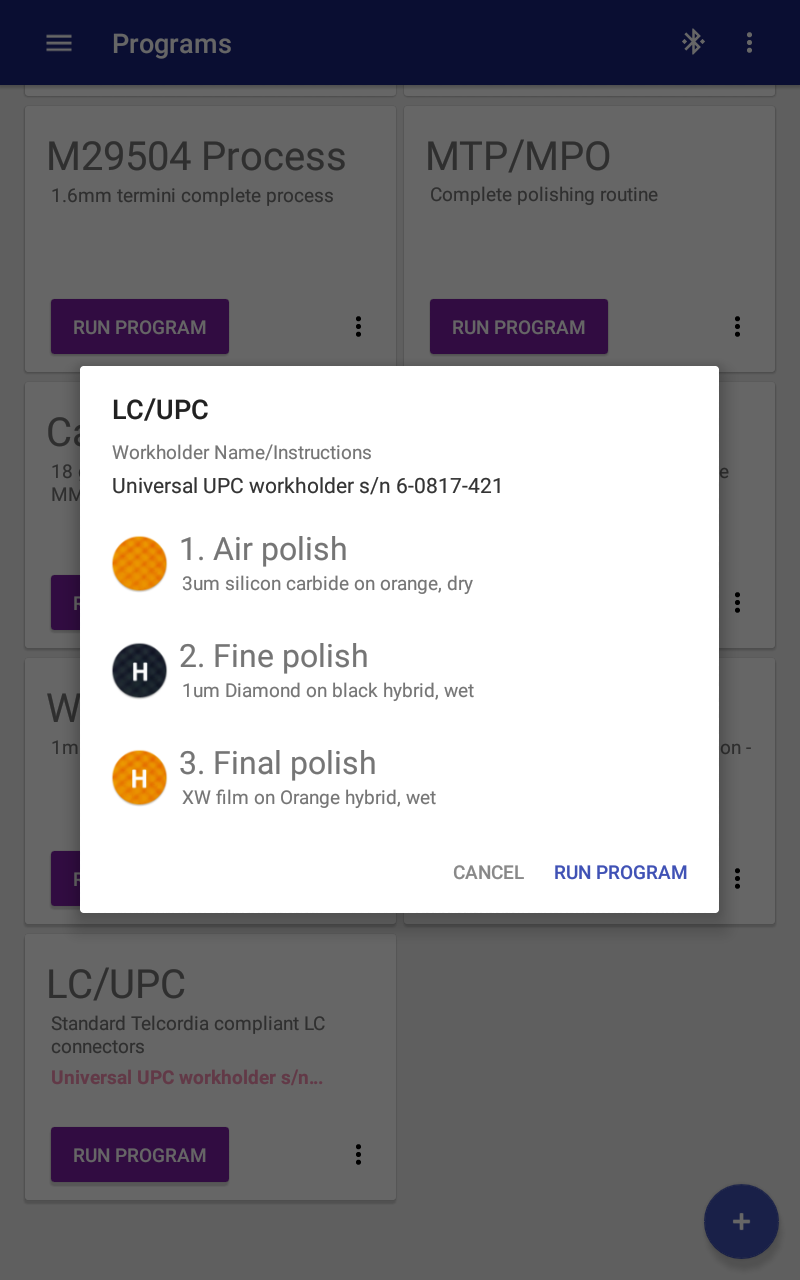

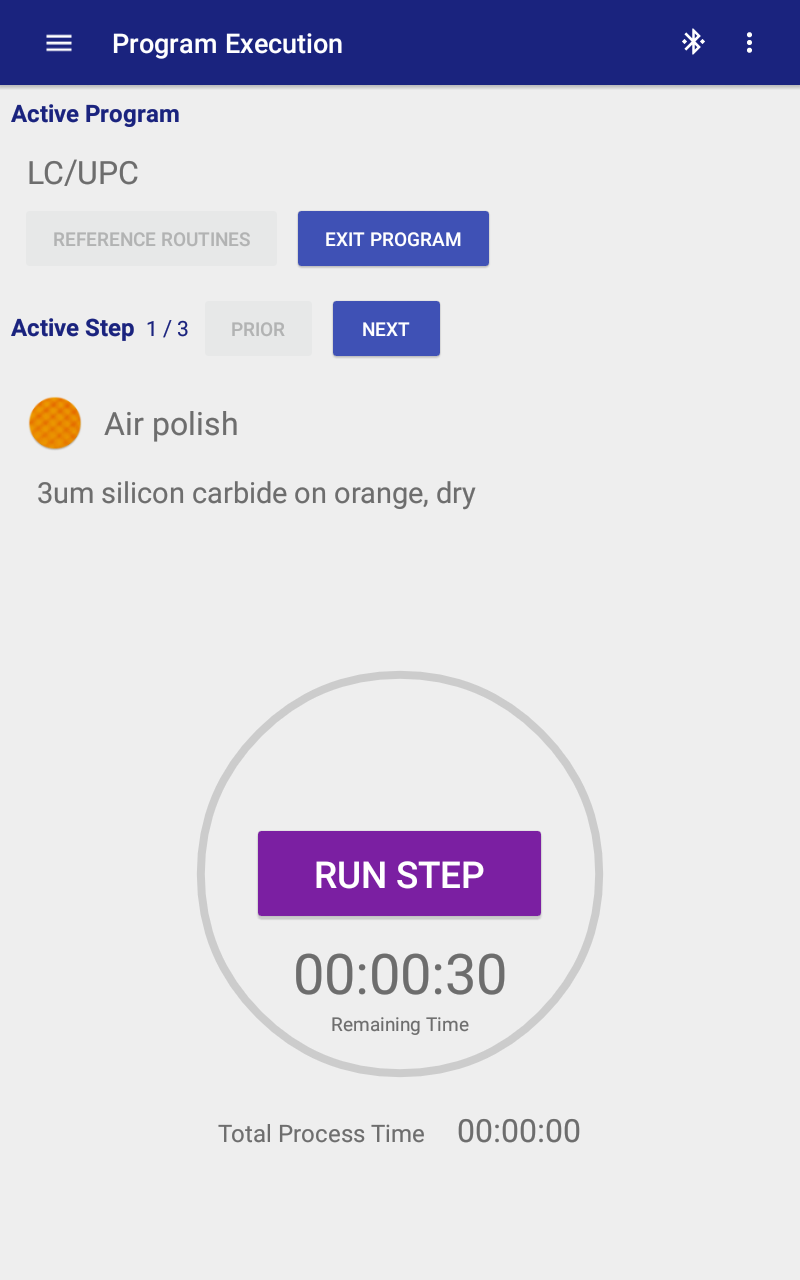

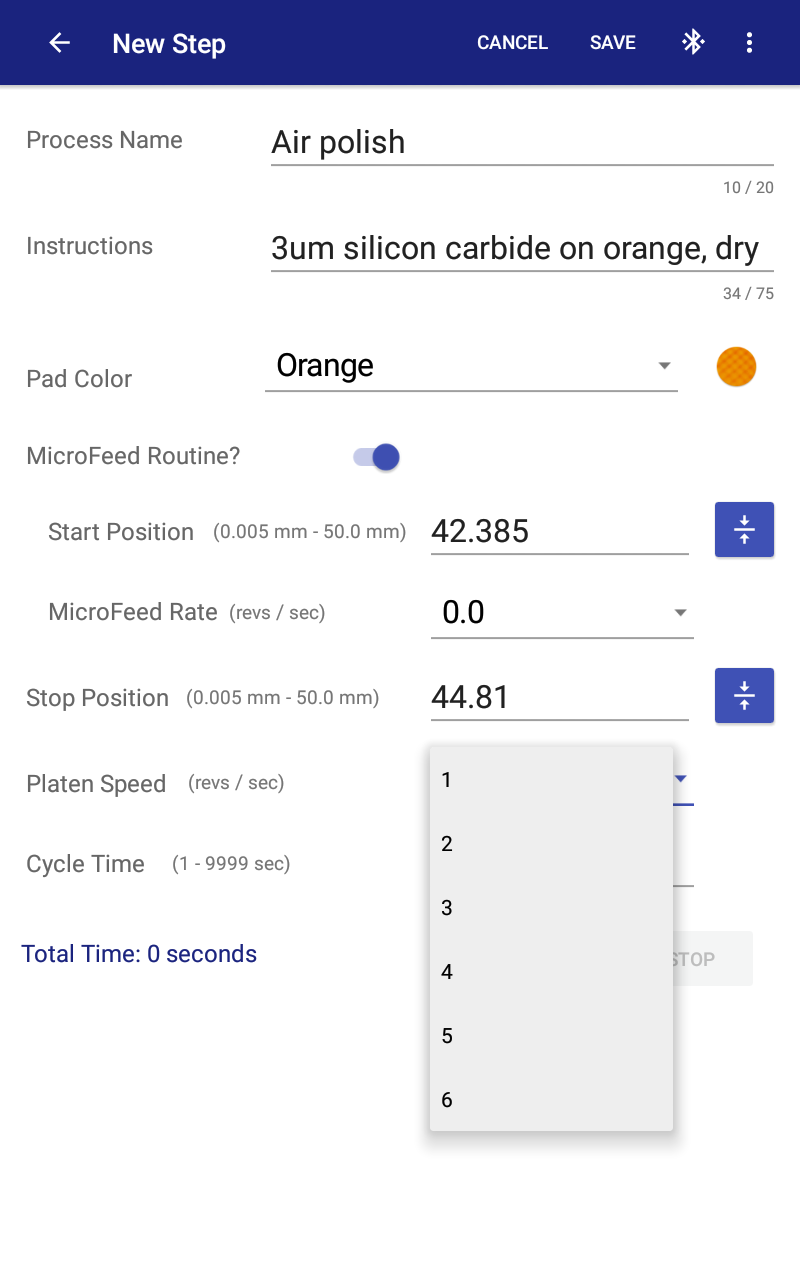

NOVA™ features an intuitive user interface for creating Cycling Timing

Program selectable

polishing programs. All parameters including cycle time, Polishing Motion

pressure and speed settings are easily inputted for all Random orbital

component types and desired surface geometries. Polishing Routines

(1) Programmable, step by step prompts

(2) Microfeed™ controlled advancement

A unique “manual mode” allows the adjustment of polishing (3) Manual mode with full process control

Film Size

parameters in real-time during NOVA™ operation. This feature 4 inch diameter.

streamlines process development efforts and facilitates easy Equipment Footprint & Weight

12” x 12” (305 x 305mm)

and quick program creation and refinement. 25lbs

1

Wired version available

Connector Performance Waveguide Performance Bare Fiber Performance

Connector Support2 Component Support Fiber Types

All industry standard connectors Waveguides, planar lightwave Singlemode, multimode, PM,

Mil-spec termini and ferrules circuits, optical chips, fiber arrays plastic, PCF, chalcogenide,

UPC & APC geometries Component Dimension Range6 sapphire and specialty fibers

Capacity Width: 5mm to 30mm Fiber Diameter

Up to 8 components. Selections Thickness: 0.5mm to 5mm 80um to >3mm

be mixed & matched in same Length: >5mm Angle Range7

workholder fixture. Angle Repeatability 0 deg. (flat) to 50 degrees

Apex Offset +/-0.3 degrees (X/Y axis along edge) Angle Repeatability

<50 microns, maximum Adjustable Polish Angle Range6 ± 0.5 degrees, typical

<15 microns, typical 0 deg. (flat) to 45 degrees

Radius of Curvature 6

7

Referenced off fiber diameter (i.e. 8° for APC style

Custom dimensions and angles available. connector polish). Custom angles available.

10-25 mm, 2.5 mm ferrules

7-20 mm, 1.25 mm ferrules

5-12 mm, APC ferrules

Inspection Options

Protrusion/Undercut3

50nm to -120 n Real-Time Polishing Inspection

Back Reflection4 80x Magnification

< -60 dB, UPC In-Line Surface Inspection

< -65 dB, APC 400x Magnification (standard)

Insertion Loss4 Coaxial Illumination

< 0.25 dB, typical Video Signal

Process Time5 EIA/NTSC Compatible

Approximately 15 sec/connector Switchable Source

2

Polishing performance meets and exceeds Telcordia/IEC. Geometry Measurements

specifications, and can be optimized for specific applications.

3

Software for angle, length and

Dependent upon radius of curvature. point-to-point measurements.

4

Optical performance may vary between connector

manufacturers Specifications subject to change without notice Rev.1, 4/17

5

Singlemode UPC/APC finish.

krell technologies, inc. · tel: (732) 775-7355 · sales@krelltech.com · www.krelltech.com

Download

Download