1

2

3

4

5

6

7

8

9

10

11

12

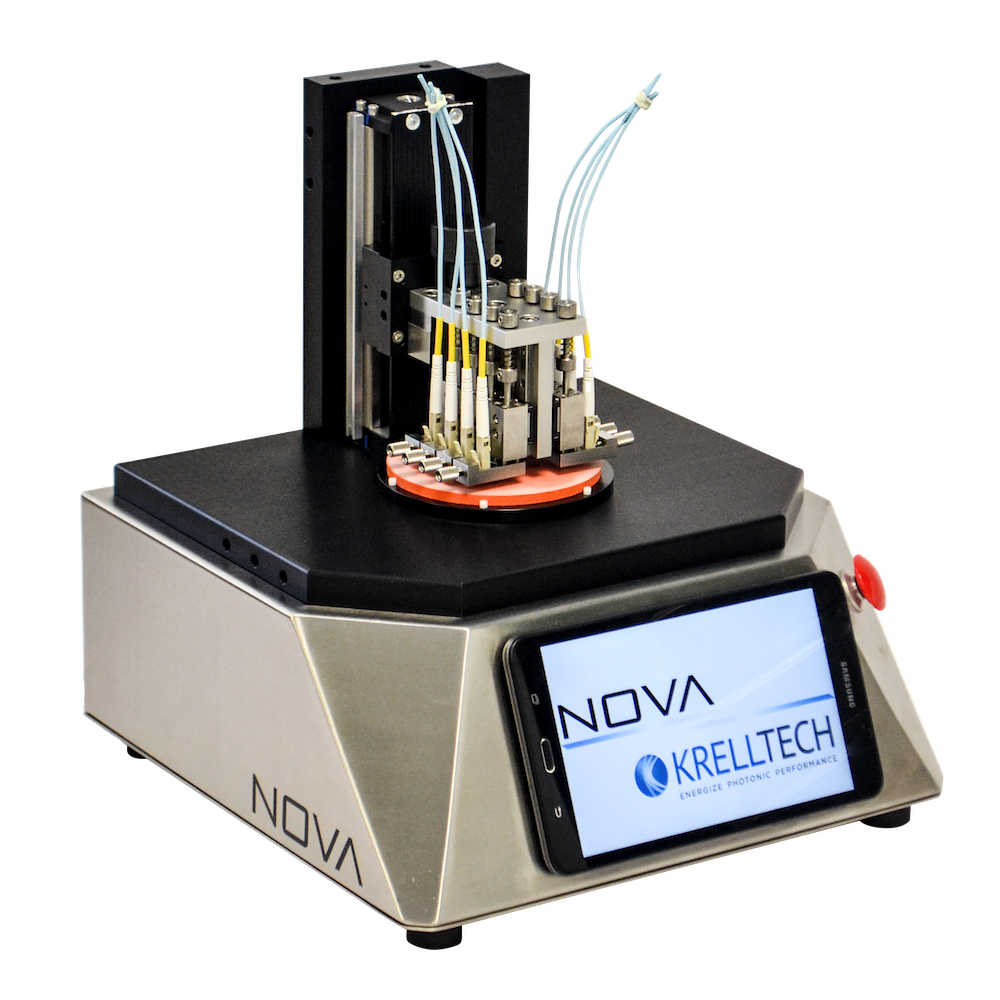

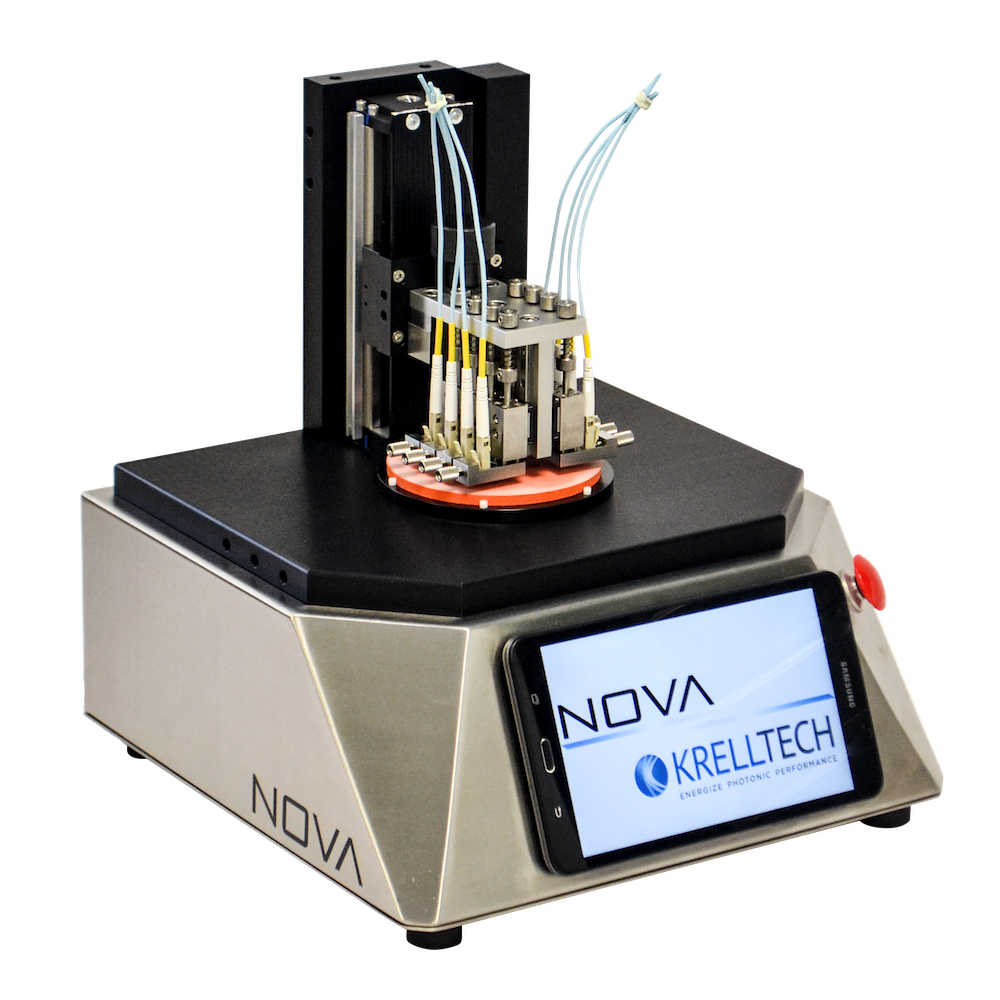

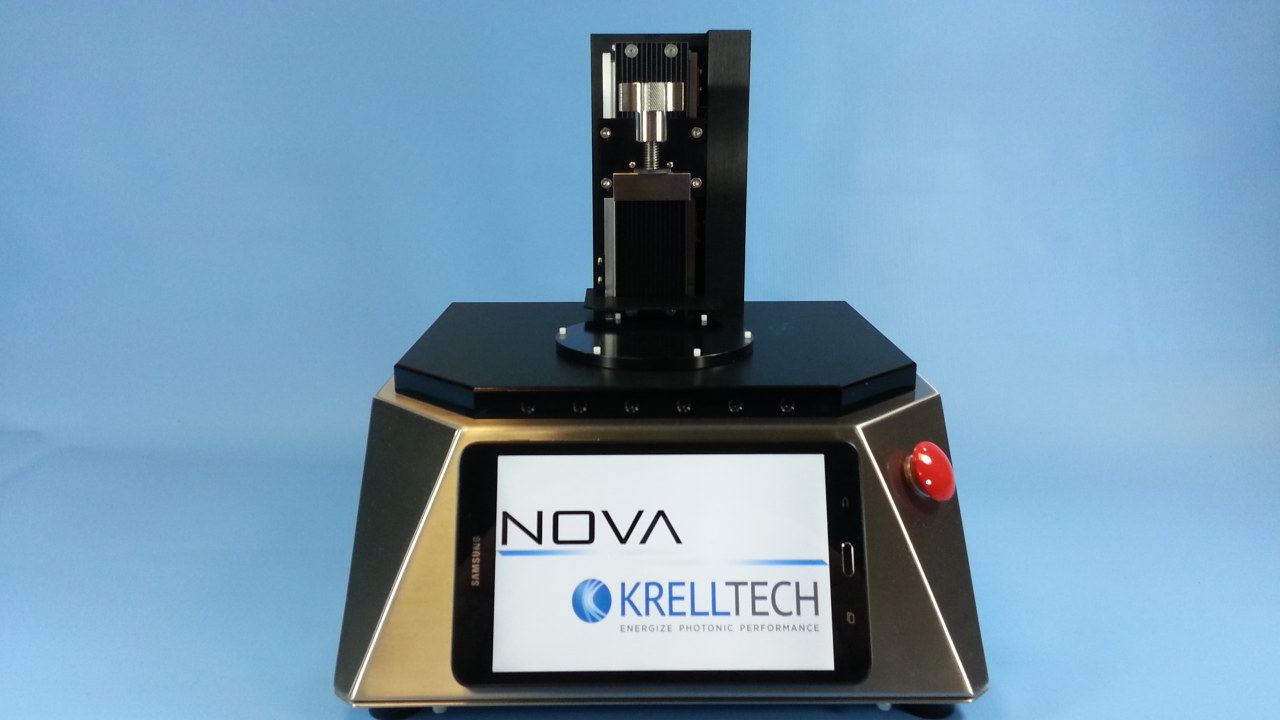

NOVA Optical Polishing System

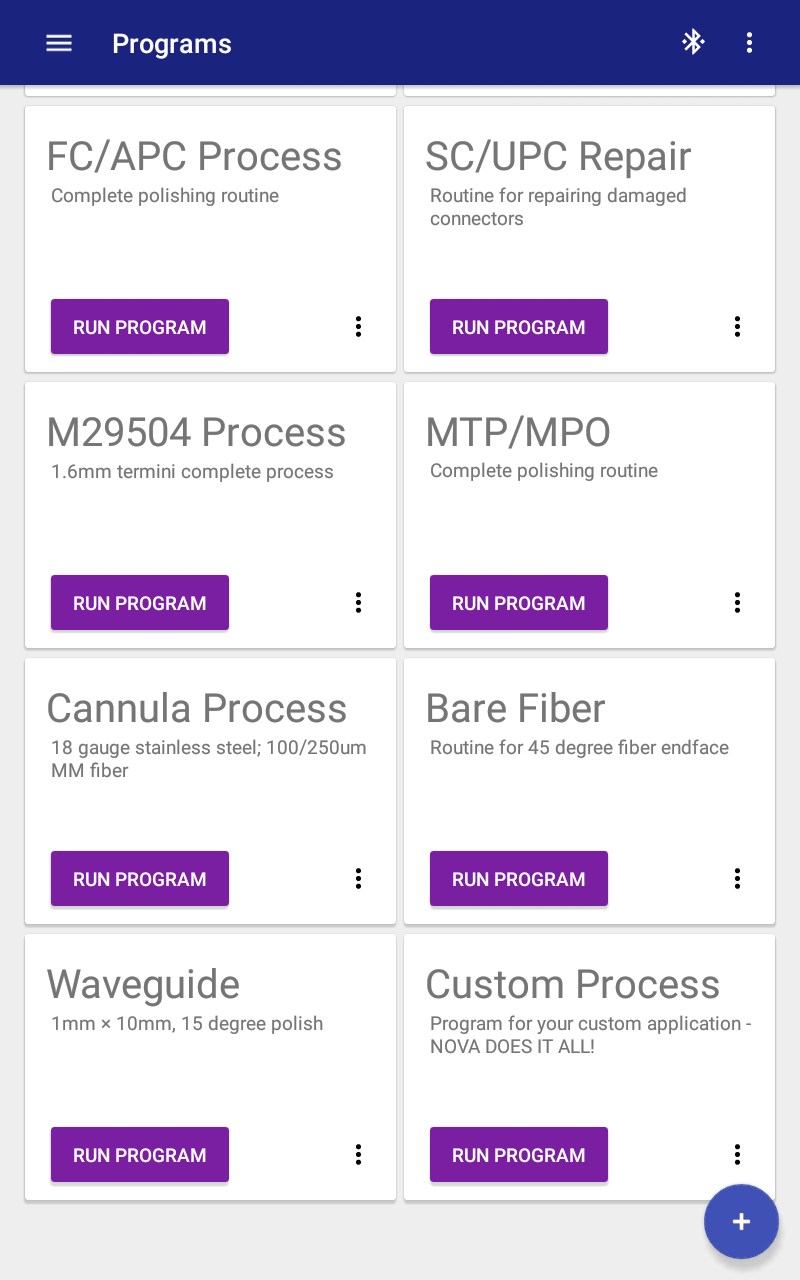

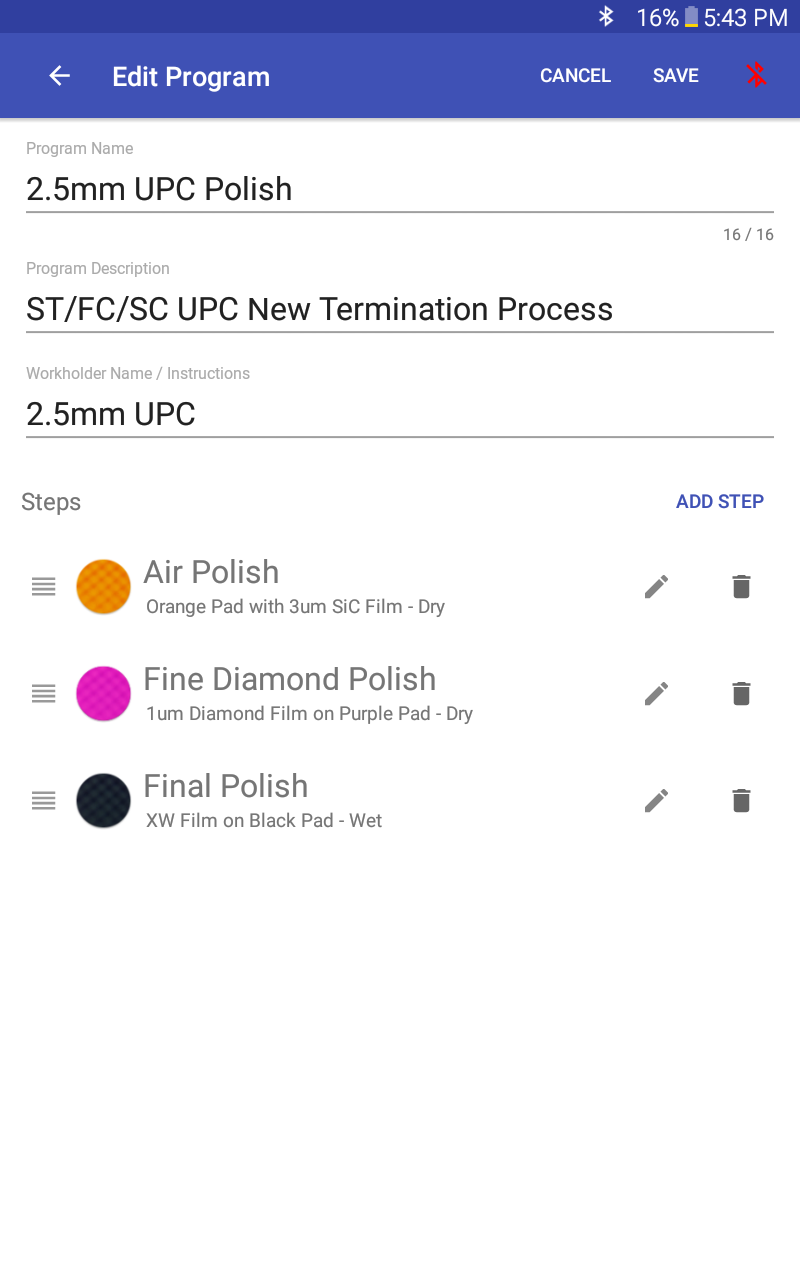

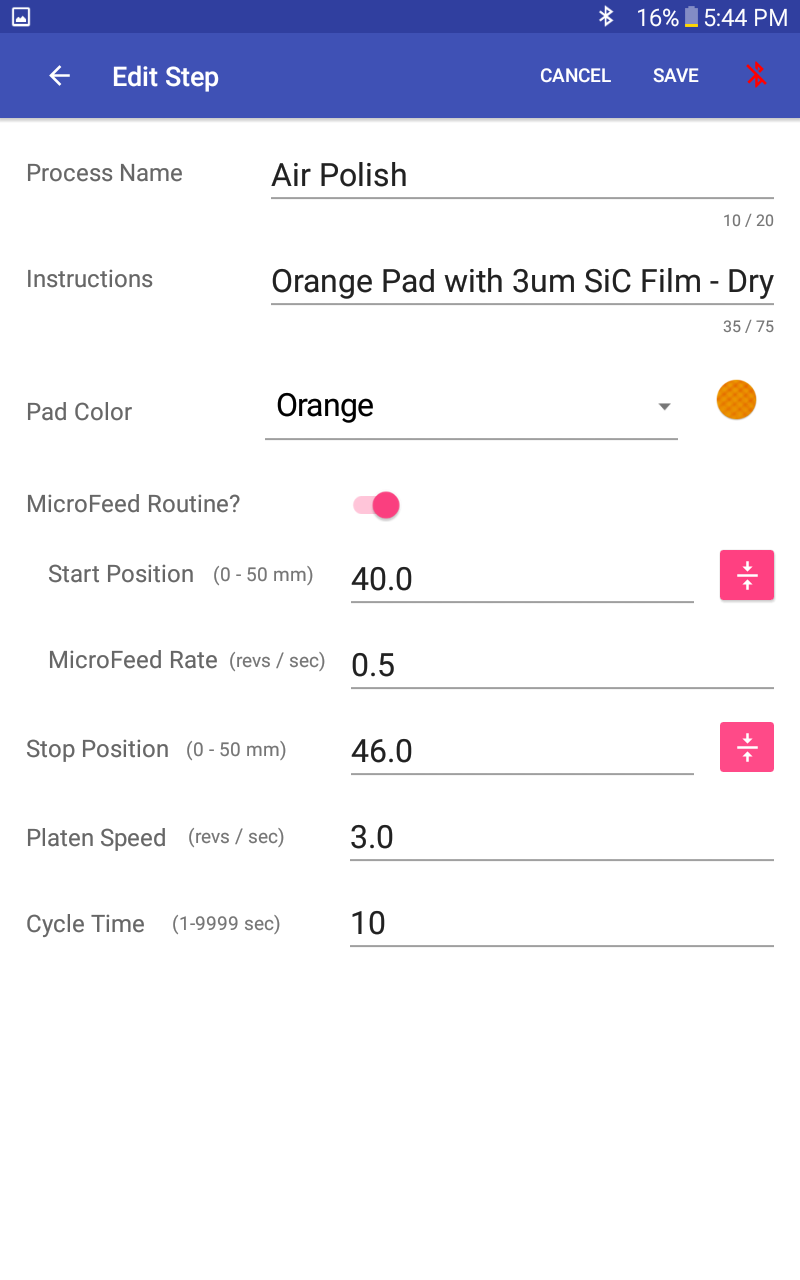

Maximum flexibility for optical surface processing is now available with NOVA™. KrellTech has integrated the proven performance and features of its industry leading Scepter, Trig and FLex polishers into this configurable and cost-effective system.

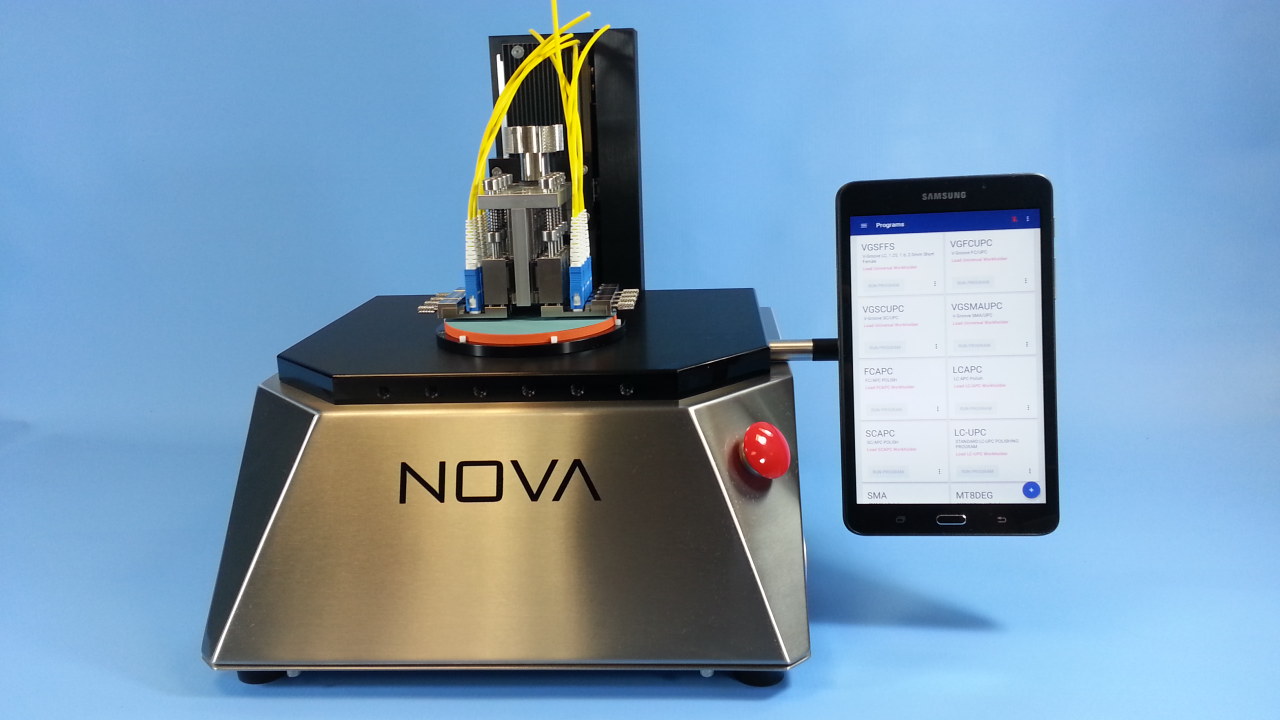

NOVA™ supports a variety of polishing applications from connectors to PICs/waveguides, and bare fibers to custom components. NOVA™ is scalable from R&D projects to high volume production and features wireless tablet operation with a familiar and intuitive Android interface.

Starting at

$ 14,950

Related Videos:

Related Q&A:

June 29, 2022, 9:41 p.m.

Q

PM fiber alignment: how well in angle can you set the stress axis?

Another way, when I couple two fibers together what the cross coupling will be.

Thanks

A

Using our SV10 Surface Inspection Videoscope combined with our measurement software, PM stress member alignment repeatability is about +/-1 degree.

May 28, 2020, 1:50 p.m.

Q

What size polishing discs are used with NOVA?

A

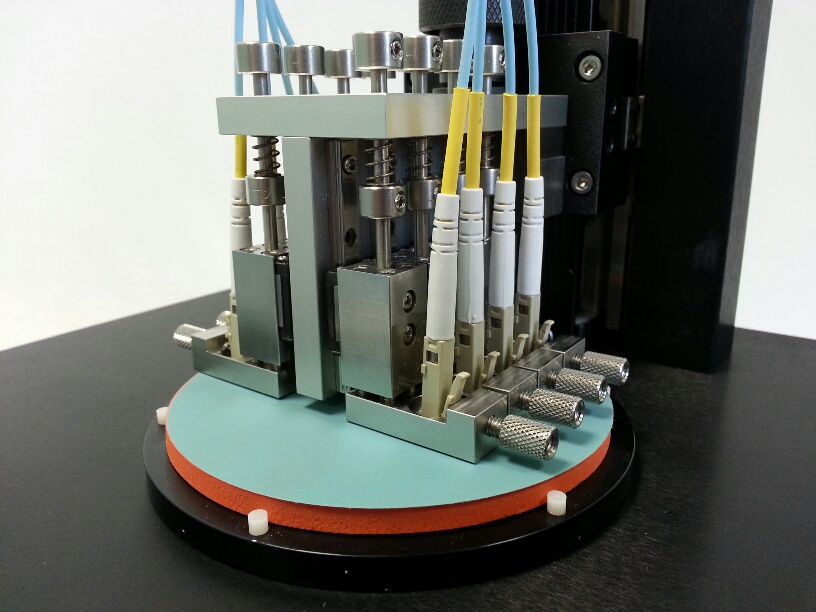

This polisher uses 4" (4 inch) diameter polishing films, rubber pads and glass disks.

April 2, 2020, 3:25 p.m.

Q

Does the NOVA offer a way to support the cables above the machine while polishing?

A

A set of cable management arms are included with the base NOVA. The NOVA design also allows for the interfacing of custom cable fixtures.

April 2, 2020, 2:49 p.m.

Q

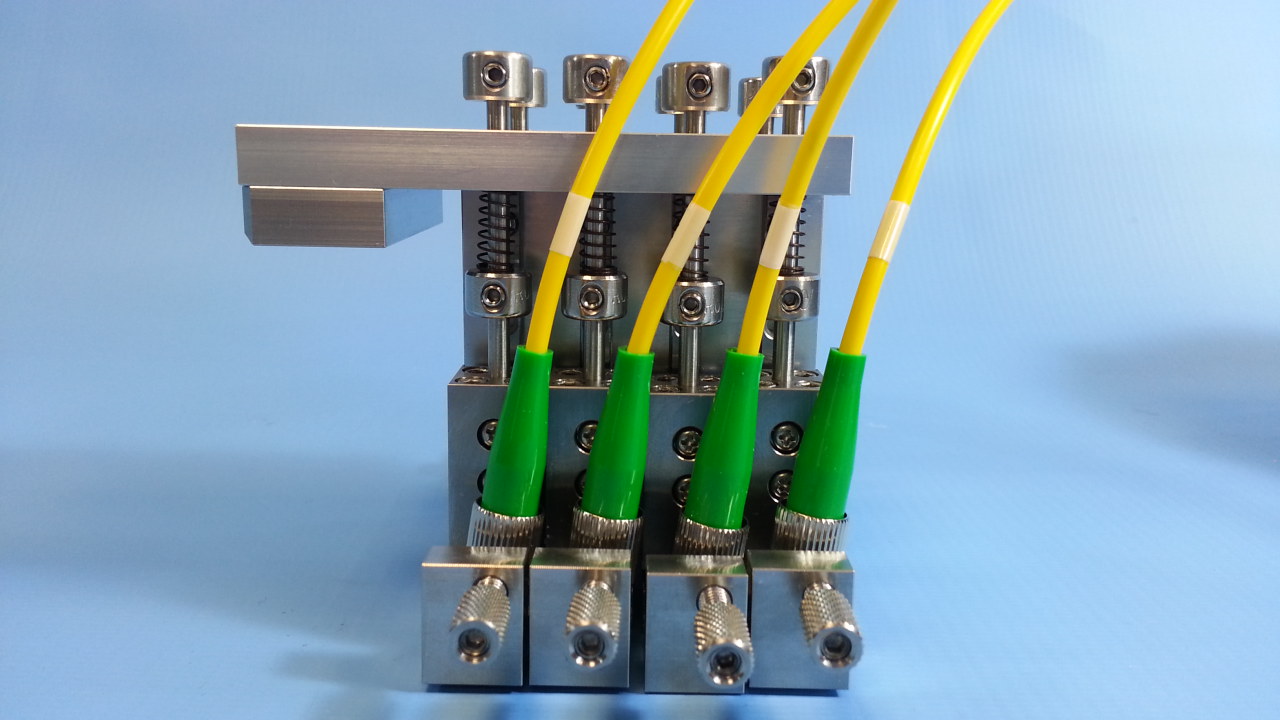

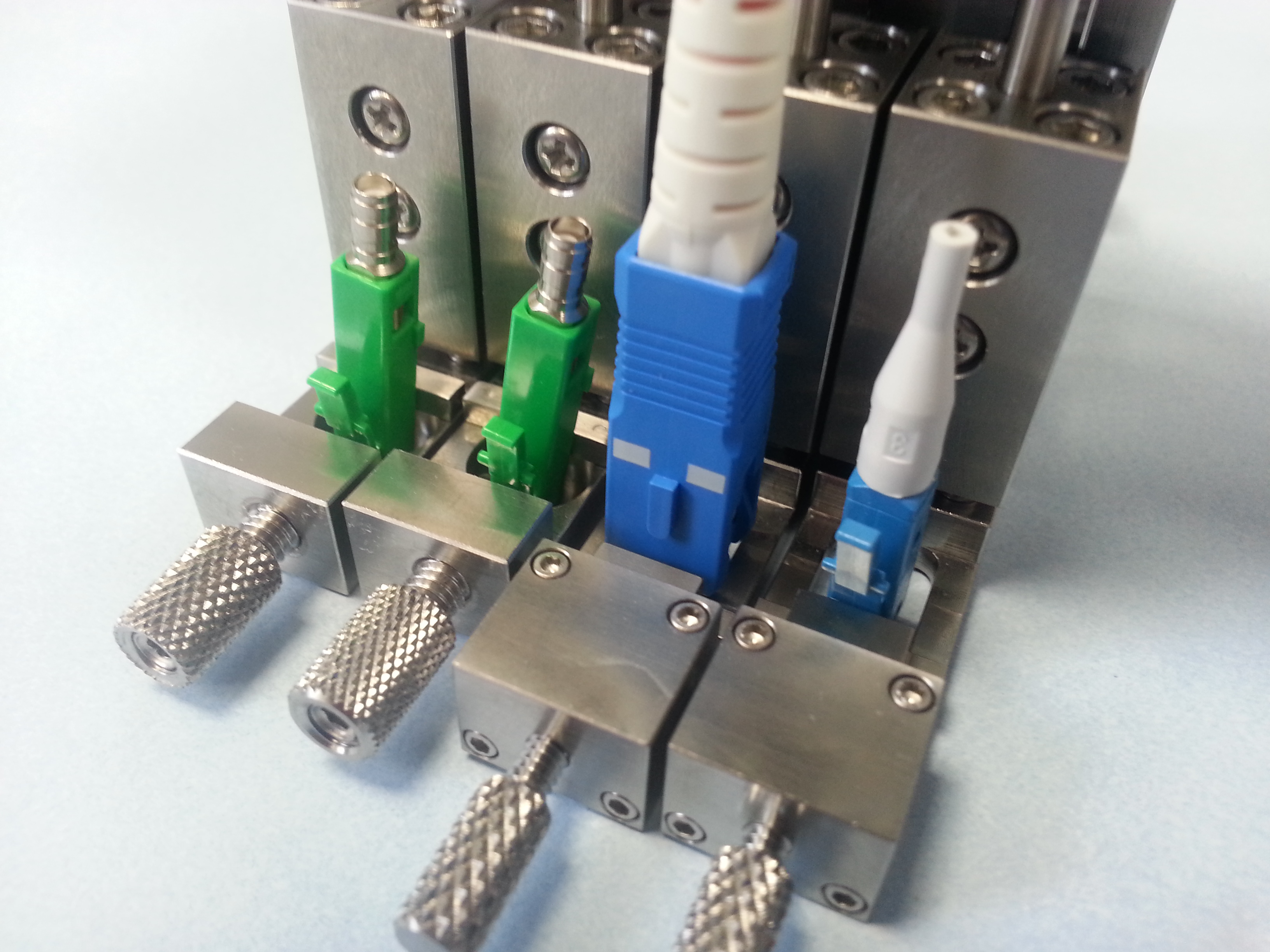

Is it possible to have different inserts for different connectors on the same 8-position NOVA?

A

Yes, an individual workholder fixture can be configured with various connector types and polishing positions.

March 31, 2020, 8:56 p.m.

Q

Is the attached a NOVA polisher?

A

No, it is a SpecPro

March 31, 2020, 8:08 p.m.

Q

I attached a picture of a product I am interested in. Can you tell me the name and part number of the attached?

A

There was no attachment provided.

March 31, 2020, 8:08 p.m.

Q

I attached a picture of polishing film and pads. Will this size work with the NOVA?

A

They appear to be all 4" in diameter, so yes.

March 31, 2020, 7:49 p.m.

Q

Is the attached compatible with a NOVA polisher?

A

No, the workholder in the picture you provided was for a Scepter Polisher.

March 31, 2020, 7:35 p.m.

Q

How is the z axis lowered to the polishing surface?

A

It uses a linear stage that is controlled via tablet.

March 27, 2020, 7:01 p.m.

Q

Is there a warranty on all parts?

A

Yes, up to 1 year.

March 26, 2020, 7:22 p.m.

Q

Is there an emergency switch button?

A

Yes

March 26, 2020, 7:13 p.m.

Q

What is the warranty period?

A

1 year on parts

March 26, 2020, 7:04 p.m.

Q

Is this base capable of interchanging workholder/fixtures?

A

Yes

March 26, 2020, 7 p.m.

Q

Are these available for angled MT Connectors?

A

Yes

March 26, 2020, 6:22 p.m.

Q

Do you offer process development?

A

We do, however on a basis to basis application.

March 23, 2020, 8:40 p.m.

Q

What film size does NOVA use?

A

4 inch diameter polishing film.

March 23, 2020, 6:37 p.m.

Q

If I have an 8 position polishing jig, can I polish less than 8 connectors?

A

Yes, any number of connectors can be polished.

Jan. 3, 2020, 4:23 p.m.

Q

What is the maximum number of SC connectors that can be polished with NOVA?

A

NOVA can polish 8 SC/UPC or SC/APC connectors.

Jan. 3, 2020, 3:20 p.m.

Q

What size film does NOVA use?

A

NOVA uses 4 inch diameter polishing film, rubber pads and glass disks.