1

2

3

4

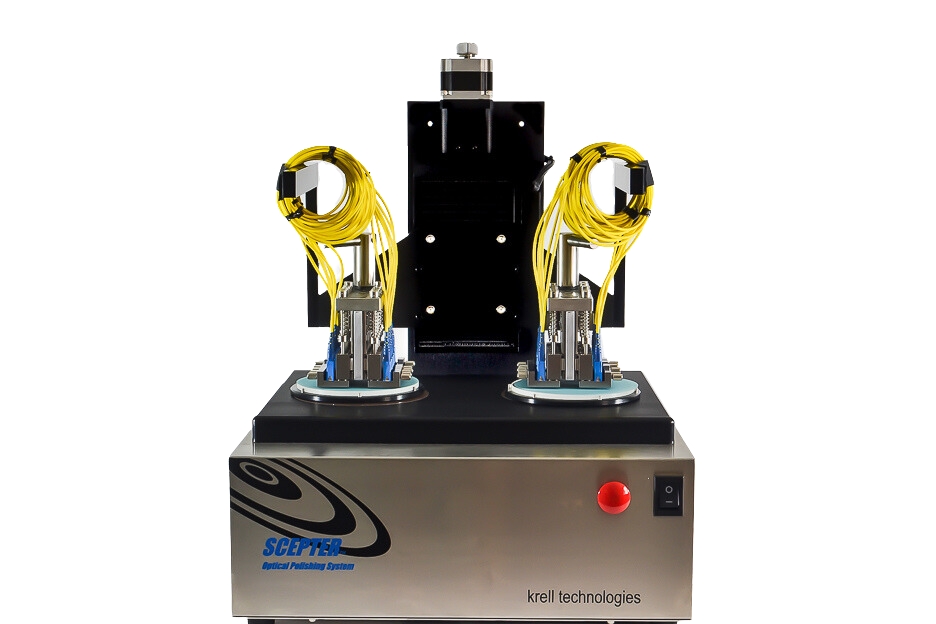

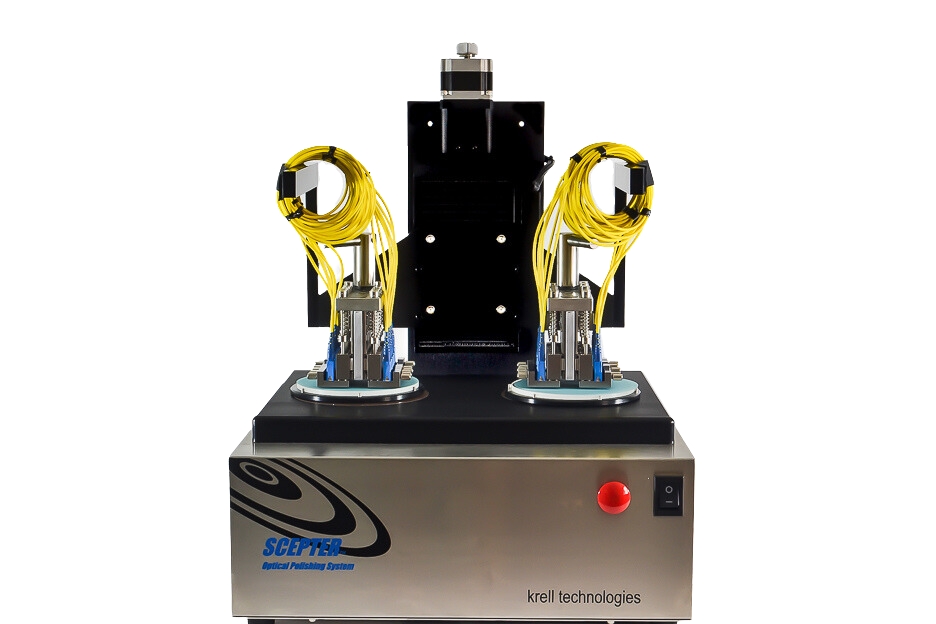

Scepter X2 Dual Position Connector Polisher

Connector polishing capacity has been doubled with the Scepter X2 System. X2 has the same footprint as KrellTech's original Scepter connector polisher, but now supports two polishing fixtures. Up to 24 connectors, Mil-spec termini and ferrules can be processed simultaneously using KrellTech's patented Independent Suspension workholders. If two High-Capacity Workholders are used, 58 components can be processed during the same polishing session. As with all KrellTech polishers, optical performance and surface geometry exceed all industry standards including Telcordia and IEC.

Starting at

$ 42,500

Related Q&A:

Nov. 24, 2020, 4:19 p.m.

Q

Are the two holes on other side of the polisher meant for another arm? See redlined photo.

A

The mounting holes you are referring to are provided for custom cable management systems, that you may want to design for special applications.

April 2, 2020, 9:36 p.m.

Q

Does the Scepter X2 have the same footprint as the standard Scepter?

A

Yes. Both polishing machines have a 17 inch length x 15 inch width footprint.

March 31, 2020, 7:54 p.m.

Q

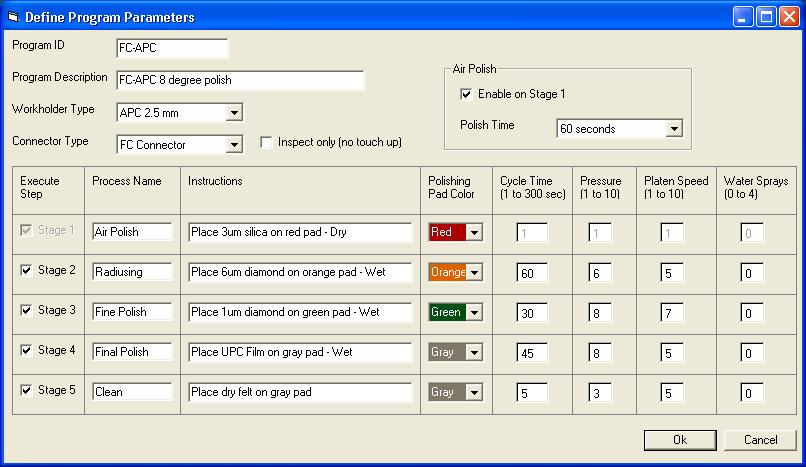

How are the workholders controlled?

A

The workholders are controlled through a computer provided by KrellTech.

March 31, 2020, 7:54 p.m.

Q

How many SC/UPC connectors can the Dual Scepter polish at once?

A

24

March 24, 2020, 6:50 p.m.

Q

Is the inspection equipment compatible with the Dual Scepter?

A

SpecVision is only compatible with the standard Scepter.

March 23, 2020, 10:14 p.m.

Q

Can NOVA fixtures be used with Scepter?

A

No. Each base polisher uses a different engagement mechanism.

Dec. 7, 2019, 9:37 p.m.

Q

Does the X2 version of Scepter use the same polishing workholders as the standard Scepter polisher?

A

Yes, X2 uses the identical polishing fixtures.