1

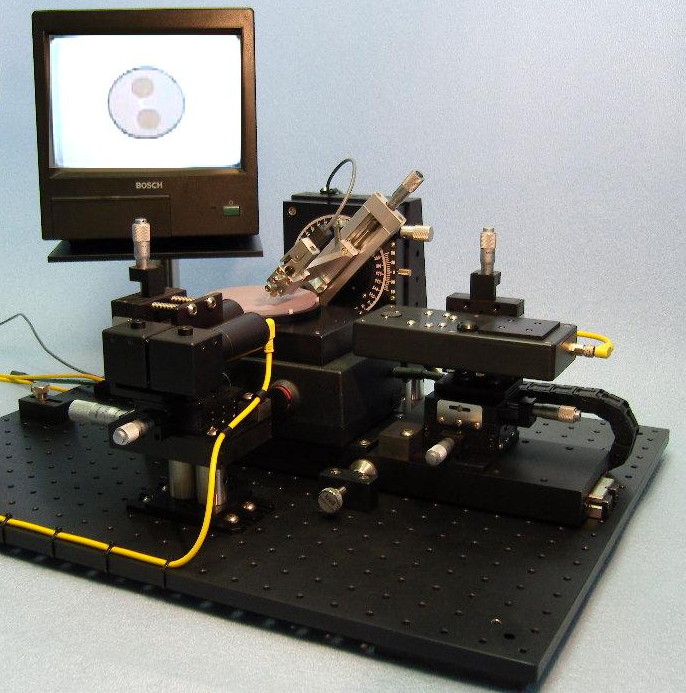

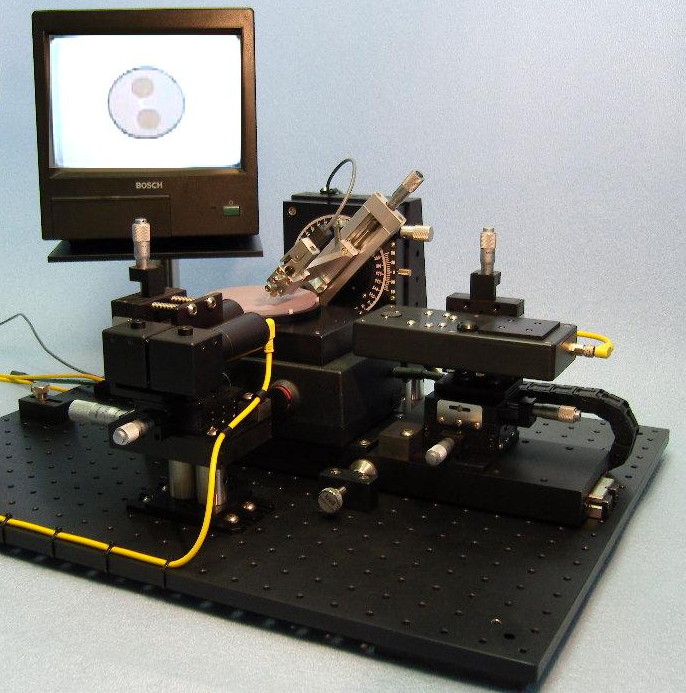

Trig™ Bare Fiber Polisher

The Trig™ System is design for processing bare optical fibers. Fiber tips can be polished flat, or at user selectable angles with high precision. Real-time video monitoring provides accurate control of the shaping process, while an in-line vision system permits inspection of the polished surface while the fiber is loaded in the machine. Interchangeable adapters are available for various fiber types and diameters. Trig™ also integrates a PM fiber alignment feature for proper angle orientation. Trig Lite™ is an optional version of the complete Trig™ system, with all features except for surface inspection.

Starting at

$ 27,000