NOVA™ System Design Considerations Shared at Photonics West

Release, June 2, 2025, 6:08 p.m.

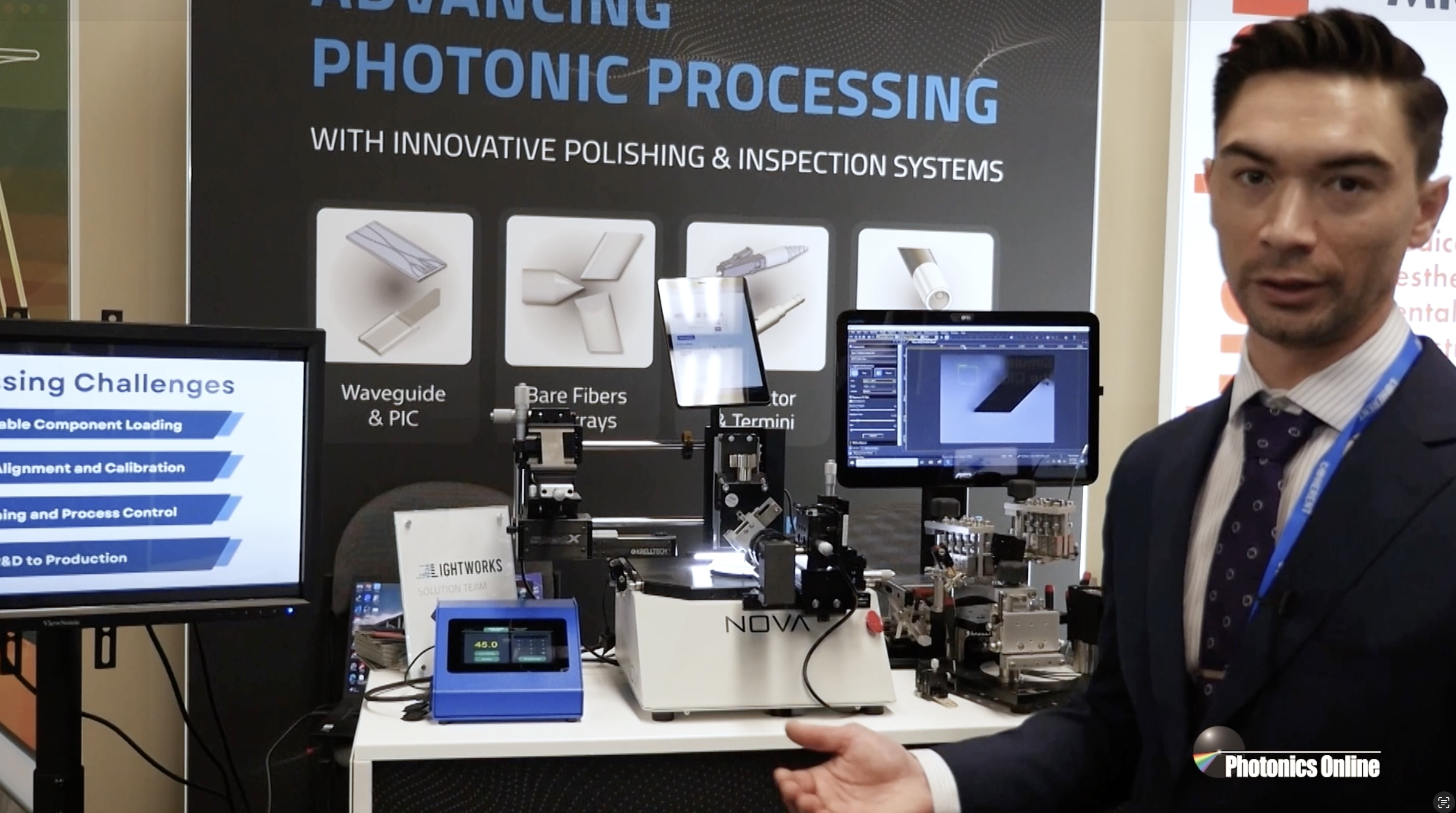

At the Photonics West trade show, Justin Frick, Director of Product Development at Krell Technologies, outlined key considerations for selecting a photonic processing machine—especially for photonic integrated circuits (PICs), waveguides, and fiber interconnects. He spotlighted how KrellTech’s NOVA™ system addresses these needs across both R&D and production-level environments.

Key Takeaways from the Interview

Safe and Precise Component Loading

When working with sensitive photonic devices, it's crucial to ensure secure, damage-free loading. The NOVA platform emphasizes defect-free clamping and carefully selected materials for precision handling.

Fixture Alignment and Calibration

Accurate polishing depends on proper alignment and calibration. Frick emphasized the importance of adaptive work holders, which help correct misalignments and maintain accuracy across varying chip geometries.

Control Over Polishing Parameters

The NOVA system offers precise control of pressure, platen speed, and cycle time—critical parameters for achieving consistent surface finishes and tight end-face tolerances in PICs.

Microfeed and 5-Micron Resolution

NOVA features a microfeed routine that slowly lowers the component to the polishing surface, maintaining contact and reducing risk of pressure spikes. Combined with its 5-micron movement resolution, this ensures consistent material removal and polishing accuracy.

Scalability from R&D to Production

NOVA supports a pathway from low-volume R&D to high-volume production, enabling upgrades like expanding from single-chip polishing to systems that polish up to four devices simultaneously.

Support for Interconnect Devices

The system’s modular workholder design allows users to polish not only PICs and waveguides but also bare fibers, fiber arrays, and connector termini—all on the same machine. This flexibility supports evolving optical packaging needs and future-proofs your investment.

Full Transcript: Photonics Online Interview with Justin Frick

0:00

So when considering a processing machine, it's important to consider a few main points.

0:04

The first is going to be reputable and safe component loading.

0:06

PICs and waveguides tend to have sensitive surfaces that need to remain scratch- and defect-free.

0:13

So not only does the clamping need to be secure, but material selection needs to be considered.

0:19

After that, your fixture alignment and calibration is also going to be very important.

0:24

Flexibility in the work holder to adapt for any changes—any misalignments in polishing orientation—is going to give you much higher accuracy in polishing. The more the polishing machine itself is going to have to have some particular polishing parameters.

0:42

That's going to include your pressure control, your platen speeds, as well as your cycle times.

0:48

The NOVA here features 5-micron resolution as well as what we call a microfeed routine.

0:54

This is a programmable feature that will lower your polishing chip to the polishing surface at a very slow rate over a certain amount of time.

1:02

This helps you maintain constant pressure with the polishing surface and ensures you don’t lose contact as material is removed.

1:14

Finally, the system must provide some sort of pathway to go from an R&D-level, low-volume process to a full-scale production line.

1:25

For instance, upgrading work holders from polishing 1 to 4 simultaneously.

1:32

Pixon Wave guys also tend to need interconnect devices.

1:35

This includes bare fibers, fiber arrays, and connector termini.

1:42

So being able to polish all of those interconnect devices by easily swapping work holders on the same PIC processing platform is going to future-proof your system and protect your investment.

1:57

So I hope that helps.

1:58

Thank you for your time.

1:59

For more information, you can find us online at www.krelltech.com.

2:03

Thank you.

Learn More

If you're working with photonic integrated circuits, waveguides, fiber connectors, or optical interconnect devices, the NOVA™ system offers the precision, flexibility, and scalability needed for both R&D and production environments.

🎤 Watch the full interview

👉 Explore the NOVA™ Polishing System

📩 Contact us at sales@krelltech.com