POLISHING EQUIPMENT

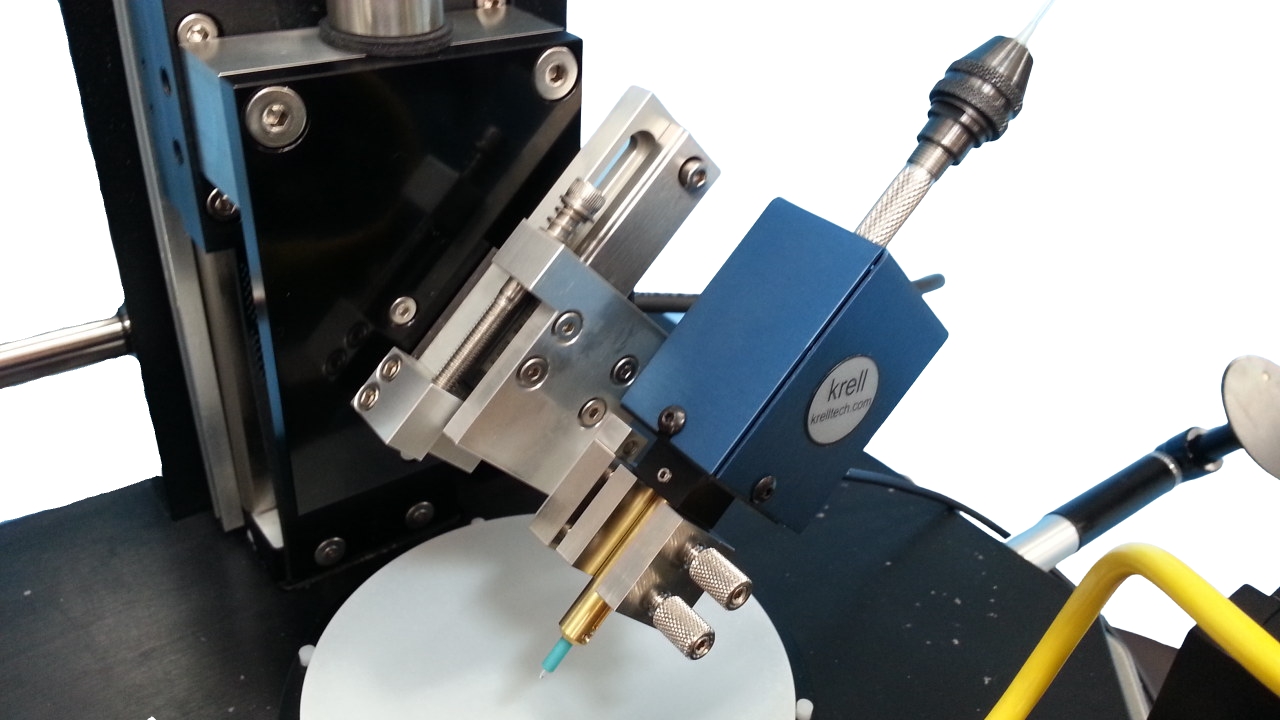

Orbit™ Bare Fiber Coning and Chisel System

Orbit™ enhances NOVA™'s bare fiber processing with conical and chisel tip shaping. Unique fiber tip geometries can be formed for lensing, sensing and light guiding applications.

The fiber rotation module can be mounted on standard NOVA™ variable angle and waveguide workholders. Fiber "spin" speed is user adjustable, and can be set for continual rotation or the unique "360 auto-reverse" motion that prevent fiber twisting and torquing.

All variables are entered and selected via a touchscreen on the Orbit™ controller. When combined with NOVA™ Auto-Angle Workholders, Orbit™ precisely positions the polishing fixture at the designed angle on a repeatable basis.

DART Bare Fiber Adapter

DART™ opens new worlds for traditional bare fiber holding. In addition to temporarily securing a fiber at a fixed position, an integrated roller mechanism moves the fiber in and out of the adapter. This allows for variable protrusion and retraction of the fiber endface relative to DART™’s precision support ferrule.

The universal 2.5mm ferrule interfaces with a variety of equipment and components such as polishers, electro-optic packages, test equipment and more. DART™ can be configured for fiber diameters ranging from 80um to >1mm using interchangeable ferrule tips.